```html

What Should I Consider When Choosing a Steel Coil Packing Machine for My Business?

As someone who's immersed in the world of manufacturing, I understand the critical role that packaging plays in the supply chain. Steel coils, with their unwieldy size and significant weight, demand careful handling and efficient packing. Choosing the right packing machine is essential to maintain product integrity and optimize operational efficiency. But with so many options out there, how do you decide which machine is the right fit for your business?

Over the years, my business has faced numerous challenges in selecting the best equipment. It’s never just a straightforward decision. Specifications, features, and costs are just the tip of the iceberg, and making the wrong choice can have long-lasting repercussions. So, what are the key considerations when selecting a steel coil packing machine? Let’s dive into the specifics.

Before I embarked on this journey, I underestimated the complexity involved in choosing packaging machinery. A single misstep can lead to operational hiccups, increased costs, and skeptical clients. Through trial, error, and a lot of research, I've identified some pivotal components that streamline the decision-making process.

Claim: Taking a comprehensive approach to evaluating steel coil packing machines can unveil hidden costs and benefits that are not immediately apparent.

1. What is the Importance of Machine Compatibility?

1.1 Understanding Equipment and Product Alignment

From the get-go, the first question that comes to mind is whether the packing machine is compatible with the specific range of steel coils we produce. Each coil varies in diameter, width, and weight. Ensuring the machine can accommodate these variations is paramount. When I initially skipped this step, I ended up with a machine that couldn't handle our largest coils, halting our production line until we found a solution.

1.2 The Technical Specifications That Matter

Technical specifications truly matter. Let’s look at some numbers to comprehend the diversity in steel coil dimensions:

| Specification | Range |

|---|---|

| Coil Diameter (mm) | 600 - 2500 |

| Coil Width (mm) | 200 - 1800 |

| Coil Weight (kg) | 500 - 25000 |

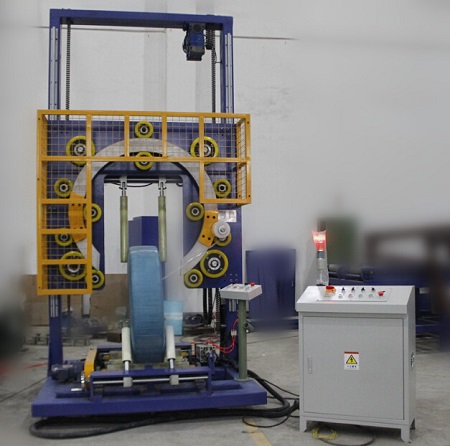

[Featured Image: A modern steel coil packing machine handling various sizes of coils]

1.3 Navigating Vendor Reliability

Vendor reliability is another crucial factor. Investing in a machine also means investing in a long-term relationship with the vendor. Their ability to provide timely maintenance and support significantly influences the machine's lifespan and efficiency.

1.4 Analyzing Operational Costs and Efficiency

Energy consumption and maintenance are ongoing considerations. Through a deep analysis, I discovered that machines with advanced technology and energy-efficient components may cost more upfront but reduce long-term operational expenses. Refer to the table below:

| Model | Energy Use (kWh/month) | Annual Maintenance Cost ($) |

|---|---|---|

| Model A | 1500 | 2000 |

| Model B | 1200 | 1800 |

1.5 Fact Statements

True: Regular maintenance of packing machines can extend their operational life by up to 30%. False: All steel coil packing machines are compatible with any type of steel coil, irrespective of size and weight.

2. How Do Technological Advancements Impact My Selection?

2.1 The Era of Smart Packaging Solutions

The role of technology in packaging has grown exponentially. The latest machines are equipped with IoT capabilities, allowing for real-time monitoring and remote adjustments. This evolution is redefining efficiency and safety standards in the industry.

2.2 Understanding the ROI of Advanced Technology

The immediate question is always about the return on investment (ROI). Here's a snapshot of potential savings from embracing advanced technology:

| Technology | Annual Savings ($) |

|---|---|

| Real-time Monitoring | 5,000 |

| Automated Adjustments | 4,500 |

[Featured Image: Diagram of a smart steel coil packing machine's control panel]

2.3 Adapting to Future Trends

Preparing for the future means staying ahead of industry trends. Investing in adaptable machines that can accommodate future expansions or technological upgrades is a strategic move. It ensures the equipment remains relevant in a rapidly evolving market.

2.4 Conclusion

Navigating the maze of selecting a suitable steel coil packing machine involves balancing immediate needs with future aspirations. By prioritizing compatibility, vendor support, operational efficiency, and technological innovation, businesses can make informed decisions that align with both current demands and future growth.

Conclusion

Choosing the right steel coil packing machine requires thorough consideration and strategic planning. By focusing on compatibility, operational costs, technological advancements, and vendor support, businesses can make decisions that ensure longevity and efficiency. The investment, both in terms of time and resources, pays off through enhanced productivity and reduced operational hurdles.

Claim: In-depth research and analysis when selecting a packing machine can save a business significant costs and operational delays.

```