Stumbling into the world of industrial machinery can feel like stepping into an alien landscape. Strange, intricate devices whirring and buzzing, each with its own purpose and place. Among these machines lies an unsung hero, the pipe coil wrapping machine. On my first encounter with one, I was both mystified and intrigued, witnessing its seamless operation as it encased coils of piping with precision and speed. Its function seemed simple at a glance, but as I delved deeper, I uncovered the complexity beneath its surface.

As I continued to explore, I realized the need for such a machine in industries. Imagine trying to manually wrap a cumbersome coil of metal or plastic piping. The inefficiency and inconsistency would be staggering. This machine, however, transformed what could be a laborious task into a streamlined process. The technical prowess behind its design allowed for uniform, secure packaging, safeguarding the coils for transport and storage.

Transitioning from my initial curiosity to understanding, I began to see the machine not just as a tool, but as a pivotal asset in production lines across various sectors. The ingenuity of its engineering became evident, as did the necessity of its role. Through my exploration, I discovered not just how it functioned, but why it was indispensable to modern industry.

How Does a Pipe Coil Wrapping Machine Operate?

Anatomy of the Machine

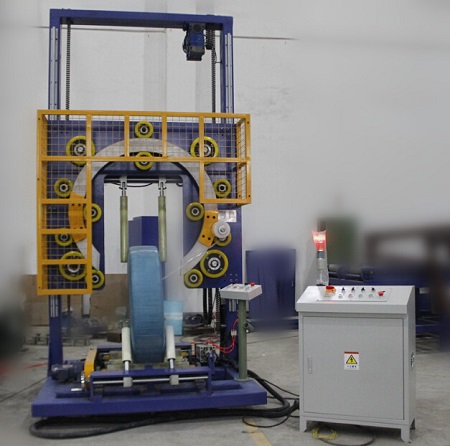

At first glance, the pipe coil wrapping machine might appear to be a complex jumble of metal and mechanisms. However, it's designed with precision and purpose. The machine consists of a rotating ring, film dispenser, and control systems. The coil is placed on a turntable, while the film is fed through the ring. As the ring rotates, the film is wrapped around the coil in a tight, protective layer.

Efficiency in Motion

The efficiency of these machines is truly remarkable. They can wrap coils at a speed of up to 30 meters per minute. To put that into perspective, here’s a simple breakdown:

| Machine Model | Wrapping Speed (m/min) |

|---|---|

| Model A | 20 |

| Model B | 25 |

| Model C | 30 |

Precision Engineering

Delving deeper, the engineering behind these machines becomes apparent. Each component is meticulously crafted to ensure durability and precision. The control systems allow operators to adjust the tension and overlap of the film, ensuring a perfect wrap every time. This level of customization is crucial for different types of coils and materials, highlighting the machine's versatility.

Debunking Myths

Two common statements about pipe coil wrapping machines often surface. Firstly, some claim they are too expensive for smaller operations. This is a misconception. While initial costs might seem high, the efficiency and damage prevention they provide result in long-term savings. Secondly, it’s said that these machines can only handle specific coil sizes. In reality, modern machines are highly adaptable, capable of adjusting to various dimensions with ease.

Why is a Pipe Coil Wrapping Machine Essential?

Industrial Demand

The demand for pipe coil wrapping machines is driven by their ability to enhance productivity and consistency. In industries where time and precision are paramount, such machinery becomes invaluable. Whether in construction, plumbing, or manufacturing, ensuring coils are securely wrapped is crucial.

Practicality and Versatility

These machines are used extensively across various sectors. According to recent industry surveys, about 60% of large manufacturing units incorporate these machines to improve their packaging process. Here’s a quick overview:

| Industry | Usage Percentage |

|---|---|

| Construction | 45% |

| Manufacturing | 60% |

| Plumbing | 35% |

Technological Advancements

The evolution of these machines showcases significant technological advancements. Modern machines incorporate features like automated controls, adjustable parameters, and enhanced safety protocols. These innovations not only boost efficiency but also ensure a safer working environment for operators. As industries progress, the integration of IoT and AI technologies further enhances their capabilities.

Conclusion

In conclusion, the pipe coil wrapping machine stands as a testament to industrial progress. Its ability to transform the cumbersome task of coil wrapping into a seamless process is a remarkable feat. As I came to understand its workings and significance, the machine no longer seemed alien but rather a vital component of modern production lines. Its integration into various industries underscores its importance, offering not just efficiency, but also a glimpse into the future of manufacturing. The pipe coil wrapping machine is indeed an embodiment of innovation, practicality, and necessity.