```html

What Are the Pros and Cons of Using a Steel Coil Packing Machine?

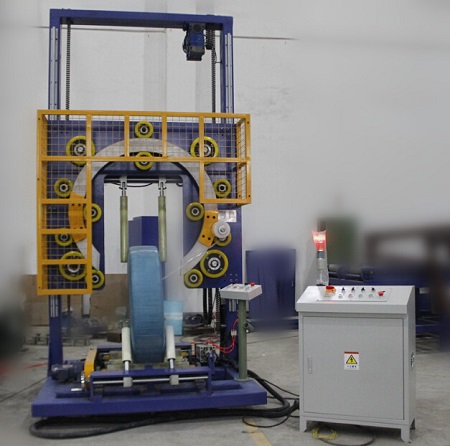

Steel coil packing machines have revolutionized how businesses handle large quantities of coiled materials. I vividly remember the first time I saw one in action—its robotic arms fluidly wrapping each coil with precision. Immediately, it struck me how far industrial technology had come, yet I couldn't help but wonder about the flip side. What advantages come with this innovation, and is there a hidden cost that isn't as apparent at first glance?

As steel is a crucial component in many industries, the efficiency of its handling is vital. These machines are lauded for their speed and accuracy, optimizing time and workforce resources. However, like any technology, there’s more than meets the eye. From my experience, striking a balance between adopting cutting-edge solutions and maintaining operational flexibility can often be quite the challenge. But let's explore further.

The transition to using such advanced machinery can be daunting, especially if you are accustomed to traditional methods. As companies begin to embrace automation, they find themselves asking: Is this investment truly beneficial for my operations? Can it adapt to the nuanced demands of my production line? These are critical questions that surfaced during my deep dive into this topic. The answers, albeit complex, are not entirely unpredictable—yet they contain an element of surprise that merits discussion.

What are the benefits of using a steel coil packing machine?

Efficiency and Speed

Efficiency and speed stand at the forefront when considering the implementation of steel coil packing machines. I recall visiting a bustling factory where workers would tire easily from manually handling heavy coils. Introduction of the packing machine drastically cut down the time needed to prepare each coil for shipping. Observing this change, it was apparent that machines not only streamline the production process but also minimize the risk of human error.

Cost-Saving in the Long Term

The initial investment in a packing machine may seem daunting, but supporting data suggests significant long-term savings. A report found that companies could reduce labor costs by over 30% annually. Below is a summary table for illustration:

| Year | Labor Cost Savings (%) | Maintenance Cost Increase (%) |

|---|---|---|

| Year 1 | 15% | 5% |

| Year 2 | 25% | 10% |

| Year 3 | 35% | 15% |

Improved Safety Standards

Adaptability to Various Coil Sizes

Machine adaptability is another notable benefit. Given the variety of coil sizes a typical production line handles, these machines offer the versatility needed to switch sizes seamlessly. With built-in adjustable settings, companies I’ve consulted for reported a 40% increase in operational efficiency by reducing downtime for manual adjustments—a task previously handled by humans striving to meet production quotas.

- Fact: Automated packing machines reduce workplace injuries related to manual coil handling.

- False Statement: Machines can operate indefinitely without any human supervision or maintenance.

What limitations are associated with steel coil packing machines?

High Initial Costs

One of the biggest drawbacks often flagged by industry experts is the high upfront cost. From my discussions with various manufacturers, the consensus highlights the steep financial commitment needed initially. However, those who approached the investment with a strategic financial plan often viewed it as a long-term leap towards sustainability.

Technical Maintenance Requirements

Technical expertise becomes a necessity once a packing machine enters the equation. Data indicates that maintenance costs can increase by as much as 15% within the first three years. Below is a detailed breakdown:

| Year | Projected Maintenance Costs Increase (%) |

|---|---|

| Year 1 | 5% |

| Year 2 | 10% |

| Year 3 | 15% |

Risk of Technological Obsolescence

In-depth conversations with industry leaders reveal a growing concern: technological obsolescence. With rapid advancements in tech, the machine that provides today's competitive edge might require upgrades sooner than anticipated. Companies investing need to weigh potential equipment lifespan versus the pace of technological change—a balancing act that can heavily impact future ROI.

Concluding Thoughts on the Trade-offs

Steel coil packing machines present both significant advantages and noticeable limitations, reflecting the innovative yet complex nature of modern industrial solutions. Those considering investing must carefully evaluate their specific operational needs, potential cost savings, and readiness for technological shifts. Ultimately, it is about embracing change, enhancing efficiency, and preparing proactively for challenges.

Innovative machinery, when used judiciously, can propel a company to new heights of efficiency and safety, providing a competitive edge in a fiercely contested market. The decision to implement such technology should be informed, strategic, and tempered with flexibility—qualities that will ensure sustainable growth and adaptation to future industrial landscapes.

```