Purchasing a hose coil wrapping machine can be a daunting task, given the myriad of options available in the market. Each machine offers unique features, and selecting the right one can significantly impact your operational efficiency and costs. Whether you're a small business owner or a large industrial player, understanding the key features of these machines is essential.

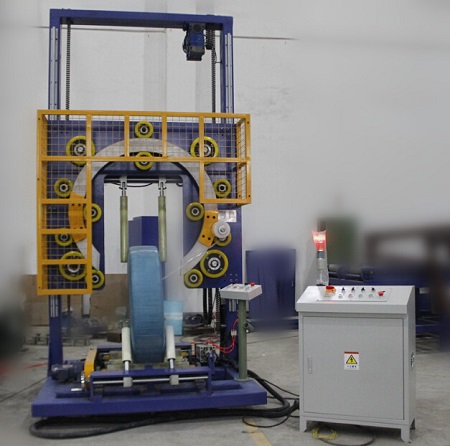

Hose coil wrapping machines are designed to automate the packaging process, ensuring that hoses are bundled securely and efficiently. These machines not only improve the speed of packaging but also enhance the safety and durability of the product during transportation. But with so many features to consider, which ones should you prioritize?

The journey of choosing the right machine begins with understanding the nuances of each feature. From automation capabilities and material compatibility to size and speed, each aspect plays a vital role in the machine's performance. Through careful evaluation, businesses can make informed decisions that align with their specific needs and budget constraints.

Claim: The right hose coil wrapping machine can revolutionize packaging operations, leading to enhanced productivity and reduced costs.

What Makes a Hose Coil Wrapping Machine Efficient?

1.1 Automation Levels: Are They Important?

Automation is a crucial factor when it comes to efficiency. A highly automated machine can operate with minimal human intervention, reducing labor costs and potential errors. Look for machines that offer programmable settings and adaptability to different hose sizes and materials. This flexibility ensures that as business needs evolve, the machine remains a valuable asset.

1.2 Measuring Efficiency: What Do the Numbers Say?

Efficiency can often be measured in numbers. Consider the speed (cycles per minute) and the machine's overall output capacity. To give you a clearer picture:

| Machine Model | Cycles per Minute | Output Capacity (Hoses per Hour) |

|---|---|---|

| Model A | 20 | 1200 |

| Model B | 25 | 1500 |

| Model C | 30 | 1800 |

1.3 Understanding Material Compatibility

Not all machines are versatile when it comes to the types of materials they can handle. It's imperative to choose a machine that is compatible with various wrapping materials such as plastic, paper, or fabric. This compatibility ensures that the machine can handle a wide range of products and can adapt to future packaging innovations.

1.4 Size and Speed: How Do They Affect Operations?

Size matters when space is limited. Machines that are compact yet powerful can fit into existing production lines without causing disruptions. Speed is equally important; faster machines increase throughput, allowing for more products to be wrapped in less time. Here's a quick comparison:

| Machine Model | Footprint (sq ft) | Maximum Speed (Hoses per Minute) |

|---|---|---|

| Model A | 10 | 25 |

| Model B | 12 | 30 |

| Model C | 14 | 35 |

1.5 Two-Fact Statement

True: Machines with advanced automation settings reduce labor costs by over 30%.

False: All hose coil wrapping machines are compatible with any type of wrapping material without modifications.

How Does Cost Influence the Decision?

2.1 Evaluating Return on Investment: What Should You Expect?

The initial cost of a hose coil wrapping machine might be high, but the return on investment (ROI) can justify the expense. Evaluating the ROI involves considering the machine's efficiency, lifespan, and maintenance costs. A well-chosen machine can pay for itself through improved productivity and reduced labor expenses.

2.2 Cost vs. Features: What’s the Real Value?

Understanding the balance between cost and features is crucial. While a lower cost might be tempting, it’s important to assess whether cheaper models offer the necessary features for your operations. Here's a breakdown of costs versus key features:

| Machine Model | Cost ($) | Key Features |

|---|---|---|

| Model A | 10,000 | Basic Automation, Limited Material Compatibility |

| Model B | 15,000 | Advanced Automation, High Material Compatibility |

| Model C | 20,000 | Full Automation, All Material Compatibility |

2.3 Understanding Maintenance Costs

Beyond the purchase price, ongoing maintenance costs can impact the budget. Machines that require frequent servicing or have expensive parts can negate the savings from automation. Select a machine with a solid warranty and a reputation for durability to ensure long-term savings.

2.4 Conclusion: Balancing Cost and Efficiency

In conclusion, the right hose coil wrapping machine should strike a balance between cost and efficiency. By focusing on key features like automation, material compatibility, and speed, businesses can achieve optimal ROI. Remember, the lowest price doesn’t always mean the best value.

Claim: Investing in the right features upfront can lead to substantial savings and enhanced operational efficiency over time.

Conclusion

Choosing the right hose coil wrapping machine involves considering a range of features that influence efficiency, cost, and compatibility. By prioritizing automation, speed, material compatibility, and balancing initial costs with long-term savings, businesses can make informed decisions that align with their operational goals. Remember that the initial investment in a high-quality machine can lead to significant productivity gains, ultimately justifying the cost.

Claim: A well-chosen hose coil wrapping machine is not just a purchase; it's a strategic investment that can transform packaging operations and drive business growth.