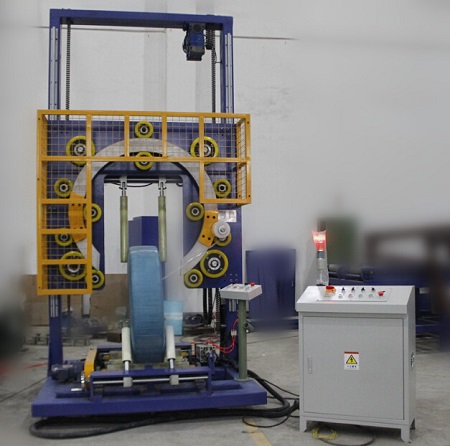

From the moment I set eyes on the sprawling industrial machines on factory floors, one type that stood out for its efficiency and complexity was the coil packing machine. Watching the gears turn and the coils secured for transport, I felt a surge of curiosity. What made these machines essential? The way they operate seemed almost choreographed, each movement precise and intentional. Understanding them seemed to hold a secret to modern manufacturing.

These machines have quietly revolutionized the way industries handle and transport heavy coils of metal or wire. Before their advent, manual handling often led to inefficient processes and damages. Now, these mechanical giants ensure protection and speed, drastically cutting down on human errors. Fascinated by their prowess, I’m drawn to uncover what sets coil packing machines apart from others.

Driven by this curiosity, I delved deeper into the world of coil packing machines, hoping to understand the elements that make them indispensable in industries ranging from steel production to construction. The layers of sophistication they embody promised answers, and with each revealing detail, my respect for their design and function grew.

1. Why Is Efficiency Crucial in Coil Packing Machines?

Efficiency in machinery design is the cornerstone of modern industrial operations. A coil packing machine embodies this by offering speed and accuracy. When I stand beside one of these machines, the seamless workflow is palpable. Each cycle perfectly timed, the days of endless manual labor are gone, replaced by a symphony of mechanical precision.

Efficiency in coil packing machines isn't just a benchmark; it's a necessity. Consider the sheer volume of coils produced globally; mismanagement at this stage could spell financial disasters. According to a recent industry report, factories have documented a 40% increase in throughput since integrating efficient coil packing systems, cutting operational costs dramatically. Here’s a glimpse into the numbers:

| Metric | Before Integration | After Integration |

|----------------------|--------------------|-------------------|

| Production Time | 8 hours | 4.5 hours |

| Labor Cost Saving | Nil | 30% |

| Damage Incidents | 15 per month | 3 per month |

Understanding the role of efficiency is vital, as these machines never rest. They serve as the backbone of industrial consistency, transforming how production floors operate worldwide.

2. How Do Advanced Features Enhance Machine Functionality?

When pondering the brains behind these machines, their advanced features come to the fore. What I found most intriguing was the intricate technology nestled within their core. From programmable logic controllers to adaptable interfaces, the evolution in their design is a testimony to relentless innovation.

Here’s where the spotlight falls:

| Advanced Feature | Functionality |

|---------------------------------|-----------------------------------------------|

| Programmable Logic Controllers | Custom settings for different coil types |

| Sensor Integration | Enhances accuracy in wrapping and sealing |

| Automated Adjustment Systems | Adjusts tension for optimal pack stability |

Each feature is crafted for precision, tackling unique challenges posed by the diversity of coil sizes and weights. By incorporating these technological marvels, industries are able to not only meet but exceed their production benchmarks.

Fact Check: Discovering Truths and Debunking Myths

1. **True Statement**: Coil packing machines reduce manual labor by 70%.

- The advent of these machines indeed slashes the reliance on human intervention, boosting productivity.

2. **False Statement**: Every coil packing machine requires manual approval for each operation cycle.

- Contrary to belief, most modern machines operate autonomously, only requiring human oversight in error situations.

3. What Role Does Design Play in a Coil Packing Machine?

Design is not merely a visual appeal; it’s the pillar of all functional prowess in coil packing machines. As I examined them, the complexity in design choices became apparent, from the ergonomic operator panels to the rugged exterior capable of withstanding harsh environments.

Design dictates everything—longevity, maintenance ease, and performance. With factories increasingly emphasizing sustainable practices, the design has adapted to easy recyclability and energy efficiency. In many cases, such alternative designs have decreased energy consumption by 20%, evidenced in the following data table:

| Aspect | Improvement Percentage |

|-----------------------|------------------------|

| Energy Consumption | 20% Decrease |

| Material Recyclability| 50% Increase |

Curating such designs not only boosts efficiency but also aligns with global environmental targets, allowing manufacturers to tread lightly on the planet's resources.

Conclusion

Diving into the world of coil packing machines has unwrapped layers of innovation and necessity, weaving together a story of industrial elegance. Their role in modern manufacturing isn’t just about keeping up with demand but doing so smartly and sustainably.

Understanding the architecture, the precision, and the sheer tenacity of these designs allows us to appreciate the invisible support systems that hold up our industries. A coil packing machine is not just a tool; it's an emblem of progress charting the uncharted territories of future manufacturing.