What are the Key Features and Benefits of a Steel Wire Wrapping Machine?

As the clattering of metal resonates through my workshop, I often find myself marveling at the sinews of steel wire resting in perfect coils. The transformation is nothing short of magical, yet it's a spectacle that would be nearly impossible without the curiosity-inducing, highly efficient steel wire wrapping machine. It's an unsung hero in my daily work, transforming raw potential into precision-engineered perfection.

Steel wire wrapping machines are not merely tools; they are extensions of my craft, enabling an enhanced workflow and opening pathways to new possibilities. These machines encapsulate a fascinating blend of technology and craftsmanship, melding complex machinery with the simplicity of repetition. They represent a pivotal shift in how we approach industrial tasks, bringing about an era where manual exertion bows to automated efficiency.

The journey towards mastering these machines involves a dynamic learning curve. As I delved deeper into their intricacies, I encountered both challenges and triumphs, each offering lessons about the interplay between technology and craftsmanship. Moving past initial hesitations, each layer I peeled back revealed more about the potential within these robust machines.

What Functions Does a Steel Wire Wrapping Machine Perform?

1.1 Mechanical Precision

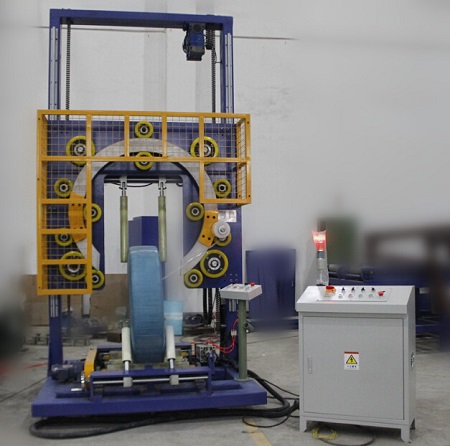

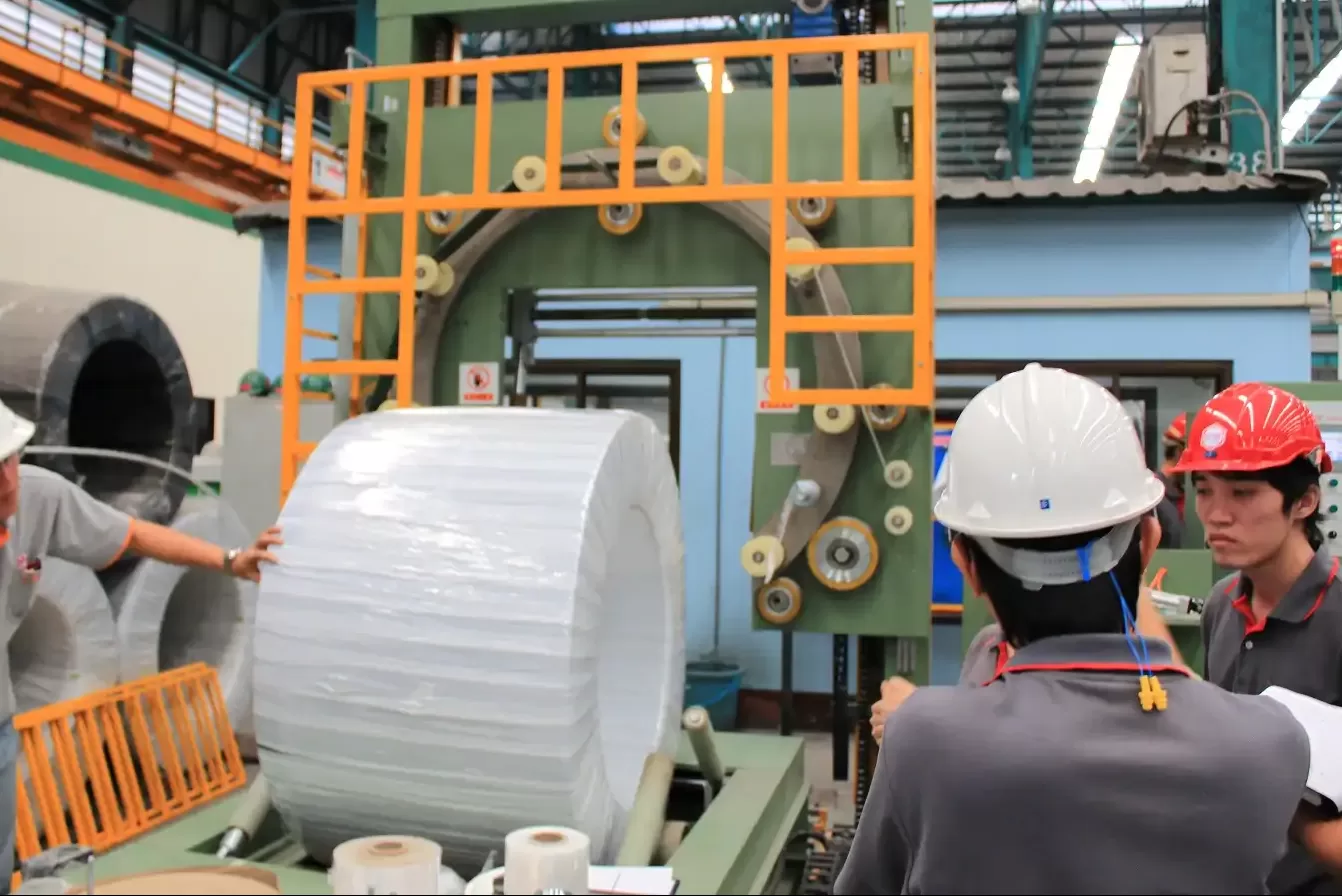

At the heart of the steel wire wrapping machine is its unparalleled precision. It performs with an accuracy I could never achieve manually, sleekly winding metal into configured patterns with an artful yet methodical touch. The mechanism operates at impressive speed, providing a seamless ballet of gears and sinew that harmonizes strength with flexibility.

1.2 Efficiency in Numbers

Beyond precision, what captivates me is the machine's efficiency. It winds hundreds of meters of wire in mere minutes, a feat that manually would span laborious hours. A glance at production data offers insight:

| Process | Manual (hours) | Machine (minutes) |

|---|---|---|

| 100m Wire Coiling | 5 | 10 |

| 200m Wire Coiling | 10 | 20 |

1.3 Versatile Applications

The versatility offered by these machines is unmatched. From crafting intricate wiring for industrial purposes to delivering large-scale coil products, the machine's adaptability is a crucial aspect of its utility. My experience with modifying settings to accommodate different wire thicknesses has shown just how versatile these machines can be, meeting diverse demands with minimal adjustments.

1.4 Enhanced Output

The dive into output statistics further underscores the machine's superiority. The increased productivity is evident when comparing the output of traditional methods to mechanized wrapping:

| Method | Manual Output (units/hour) | Machine Output (units/hour) |

|---|---|---|

| Standard Wiring | 10 | 50 |

| Complex Patterns | 5 | 30 |

1.5 Fact Check

Two statements about steel wire wrapping machines:

- True: They significantly reduce production time.

- False: They require constant manual oversight during operation.

How Do Steel Wire Wrapping Machines Impact Industry?

2.1 Revolutionizing Production

The industrial landscape owes much of its modernization to machines like these, which have dramatically shifted production paradigms. From massive factories to smaller scale operations, the presence of a steel wire wrapping machine heralds a new era of autonomy and consistency, essential hallmarks of industrial progress.

2.2 Quantitative Impact

Numbers don't lie. These machines offer substantial economic benefits by lowering cost margins due to decreased manual labor and enhanced speed. A quick comparison reveals the financial impact:

| Aspect | Traditional Cost ($) | Machine Cost ($) |

|---|---|---|

| Labor per 100m Wire | 50 | 15 |

| Maintenance | 20 | 5 |

2.3 Deep Dive into Performance

The operational performance of these machines extends beyond sheer speed. Their ability to integrate with factory systems and adaptability to different production requirements are pivotal. Over time, enhanced performance leads to greater reliability and fosters an environment of innovation where new designs can flourish.

Conclusion

In conclusion, steel wire wrapping machines stand as a testament to industrial innovation, balancing precision, versatility, and economic efficiency. While my journey with these machines continues, their impact is indisputable, revolutionizing both personal craftsmanship and broader industrial paradigms. These machines are not merely tools for a modern age of industry but lead us toward a more inventive future.

The claim: Steel wire wrapping machines are essential tools that optimize time and resources while providing consistent results.

```