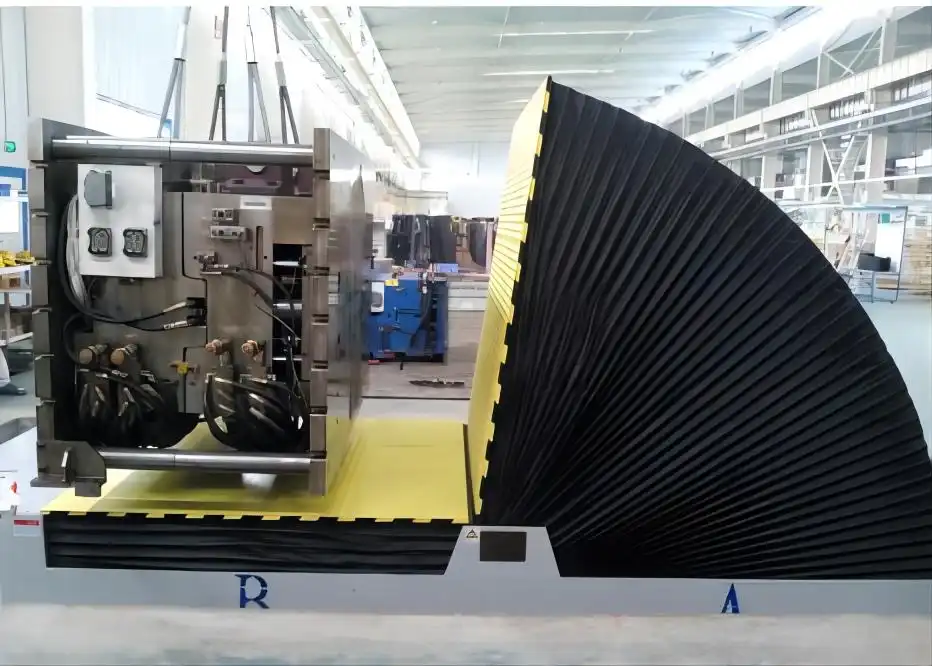

The world of manufacturing is vast and intricate, yet certain tools stand out for their indispensable roles. Among these, the mold upender has emerged as a pivotal asset in China’s bustling industrial landscape. As the global powerhouse of manufacturing, China’s factories churn out everything from intricate electronics to sturdy automotive parts, each requiring precision molds. These molds, often hefty and cumbersome, necessitate specialized equipment to handle them efficiently and safely. Enter the mold upender, a machine designed to rotate heavy molds with ease, minimizing manual labor and enhancing operational safety.

In essence, the mold upender revolutionizes how molds are handled in manufacturing settings. Consider a factory floor where molds weighing several tons need repositioning. Without an upender, such tasks would demand significant manpower and time, not to mention the increased risk of accidents. But with the upender, the process is streamlined, allowing for swift and safe transitions. In China, where efficiency and productivity are paramount, the mold upender has become more than just a tool; it's a cornerstone of the industry’s operational framework.

Yet, the true significance of the mold upender in China extends beyond its immediate utility. It reflects a broader trend: the relentless pursuit of technological advancement and operational excellence. As we delve deeper into this topic, the myriad benefits and transformative impact of mold upenders in China's manufacturing sector will become evident. Claim: The mold upender is a testament to the strides China has made in optimizing manufacturing processes, ensuring safety, efficiency, and unparalleled productivity.

How Does a Mold Upender Enhance Factory Safety and Efficiency?

When we examine the inner workings of a factory, safety and efficiency often emerge as the two most critical concerns. In China, where industrial operations scale to massive levels, ensuring these two factors becomes paramount. Mold upenders play a vital role in addressing these concerns.

Imagine a typical day on a Chinese factory floor, where workers are tasked with handling large molds. Without an upender, the risk of injury is significant. Lifting or tilting these heavy molds manually not only poses a physical risk to the workers but also increases the likelihood of damaging the molds themselves. Mold upenders, however, mitigate these risks by automating the rotation process, thus ensuring that molds are handled safely and precisely.

Moreover, the efficiency introduced by mold upenders is incomparable. A task that might have taken several workers and hours to complete can now be accomplished by a single operator in a matter of minutes. This not only reduces labor costs but also minimizes downtime, allowing factories to maintain continuous production cycles.

Additionally, the precision offered by mold upenders ensures that molds are less likely to suffer from mishandling, which can lead to defects and increased production costs. In an industry where margins can be thin, such efficiencies are invaluable.

Ultimately, the mold upender not only enhances the safety of factory operations but also significantly boosts efficiency, making it an indispensable tool in China's manufacturing arsenal.

What Is the Economic Impact of Mold Upenders in China's Manufacturing Sector?

A closer look at the economic implications of mold upenders reveals their profound impact on China's manufacturing landscape. By streamlining operations, these machines contribute significantly to cost savings and productivity enhancements.

| Year | Adoption Rate (%) | Productivity Increase (%) |

|---|---|---|

| 2010 | 20 | 5 |

| 2013 | 35 | 12 |

| 2016 | 50 | 18 |

| 2019 | 65 | 25 |

| 2022 | 80 | 30 |

From the table above, it's evident how the adoption of mold upenders has steadily increased over the years, leading to significant productivity gains. This upward trend reflects the growing recognition of mold upenders as a catalyst for economic growth within the manufacturing sector.

The economic benefits are twofold. Firstly, by reducing manual labor and increasing efficiency, factories can lower operational costs. Secondly, the enhanced precision and reduced risk of damage translate into higher quality outputs, which in turn can lead to increased competitiveness in global markets.

In conclusion, the economic impact of mold upenders is substantial, driving both cost savings and productivity improvements across China's manufacturing sector.

How Do Mold Upenders Influence Product Quality and Consistency?

Product quality and consistency are the hallmarks of successful manufacturing operations. In China, where production volumes are staggering, maintaining these standards is critical. Mold upenders contribute significantly to achieving these goals.

Firstly, the precision with which mold upenders handle molds ensures that each mold is positioned accurately for production. This precision reduces the likelihood of defects, which can compromise product quality. When molds are consistently handled with care, the consistency of the final product improves.

Moreover, the automation involved in mold upender operations eliminates human error, a common cause of inconsistencies in production. By standardizing the mold rotation process, the upenders ensure that each production cycle is identical, thereby enhancing the uniformity of the output.

Furthermore, consistent mold handling reduces wear and tear on the molds themselves, prolonging their lifespan and maintaining the quality of the production process over time. This is especially important in industries such as automotive and electronics, where precision and durability are paramount.

In essence, mold upenders play a crucial role in ensuring product quality and consistency, reinforcing China’s reputation as a leader in efficient and reliable manufacturing.

What Are the Technological Advancements in Mold Upenders?

The evolution of mold upenders is a testament to the continuous technological advancements in the manufacturing sector. In recent years, these machines have seen significant upgrades, enhancing their functionality and efficiency.

| Feature | 2010 | 2023 |

|---|---|---|

| Load Capacity (tons) | 5 | 15 |

| Rotation Speed (rpm) | 1 | 3 |

| Automation Level | Manual | Fully Automated |

| Safety Features | Basic | Advanced |

| Energy Consumption (kW) | 10 | 6 |

From the table, it's clear that mold upenders have become more sophisticated over time. The increase in load capacity and rotation speed, coupled with a shift towards full automation, reflects the technological strides made in this field.

These advancements have not only improved the efficiency of mold handling but also enhanced the safety and energy efficiency of the operations. The introduction of advanced safety features has further reduced the risk of accidents, making mold upenders even more indispensable in the manufacturing sector.

In conclusion, the continuous technological advancements in mold upenders underscore their essential role in modern manufacturing, driving efficiency, safety, and sustainability.

What Are Some Myths and Facts About Mold Upenders?

In the world of manufacturing, myths often circulate alongside facts, creating a cloud of misinformation. When it comes to mold upenders, distinguishing between what’s true and what’s not is crucial for informed decision-making.

One common myth is that mold upenders are only necessary for large-scale operations. This is false. While they are indeed invaluable in large factories, they also provide significant benefits to smaller operations, enhancing safety and efficiency regardless of scale.

On the factual side, it's true that mold upenders significantly reduce the risk of workplace injuries. By automating the mold rotation process, these machines minimize the need for manual labor, protecting workers from potential harm.

Another myth is that investing in mold upenders is too costly for most manufacturers. While the initial investment can be substantial, the long-term savings in labor costs and increased productivity often offset the initial expenditure, making them a cost-effective solution.

In summary, while there are misconceptions about mold upenders, understanding the facts reveals their true value and versatility in the manufacturing sector.

How Are Mold Upenders Integrated into Modern Manufacturing Processes?

In the ever-evolving landscape of modern manufacturing, integrating new technologies is key to staying competitive. Mold upenders have become seamlessly integrated into these processes, offering a multitude of benefits.

In industries such as automotive manufacturing, where precision and efficiency are paramount, mold upenders play a crucial role. They allow for the smooth transition of molds between different stages of production, ensuring that each component is produced with the utmost accuracy.

In electronics manufacturing, where delicate components are the norm, mold upenders prevent damage by providing a stable and controlled environment for mold handling. This minimizes the risk of defects and enhances the overall quality of the products.

Furthermore, in the realm of heavy machinery production, mold upenders manage the substantial weight of molds with ease, streamlining the production process and reducing the physical strain on workers.

In essence, mold upenders have become an integral part of modern manufacturing processes, driving efficiency, precision, and safety across diverse industries.

What Are the Economic Benefits of Mold Upenders in Various Industries?

The economic benefits of mold upenders extend across various industries, providing cost savings and efficiency improvements that boost competitiveness.

| Industry | Cost Savings (%) | Efficiency Improvement (%) |

|---|---|---|

| Automotive | 10 | 20 |

| Electronics | 12 | 18 |

| Heavy Machinery | 15 | 25 |

| Aerospace | 8 | 15 |

| Consumer Goods | 5 | 10 |

From the table, it's evident that mold upenders bring substantial economic benefits across various industries. The cost savings and efficiency improvements they offer contribute to increased competitiveness and profitability.

In conclusion, mold upenders have become essential tools in modern manufacturing, driving economic benefits and enhancing the efficiency and precision of production processes.

What Are the Key Takeaways from the Role of Mold Upenders in Manufacturing?

The role of mold upenders in manufacturing is multifaceted, offering a range of benefits that enhance safety, efficiency, and economic viability. They have become indispensable tools in various industries, driving improvements in productivity and product quality.

By automating the mold handling process, mold upenders minimize the risk of workplace injuries and reduce labor costs, making them a cost-effective solution for manufacturers. Their integration into modern manufacturing processes has driven efficiency and precision, enhancing the competitiveness of industries such as automotive, electronics, and heavy machinery production.

In summary, mold upenders are essential tools in modern manufacturing, driving economic benefits and enhancing the efficiency and precision of production processes.

Conclusion

In conclusion, the mold upender is a vital component of China’s manufacturing sector, providing substantial benefits in terms of efficiency, safety, and economic viability. By automating the mold handling process, these machines enhance productivity and product quality, driving economic growth across various industries. As manufacturing processes continue to evolve, mold upenders will remain a key driver of progress and innovation. Claim: The mold upender is an indispensable tool that underscores China’s commitment to technological advancement and operational excellence in the manufacturing sector.