`

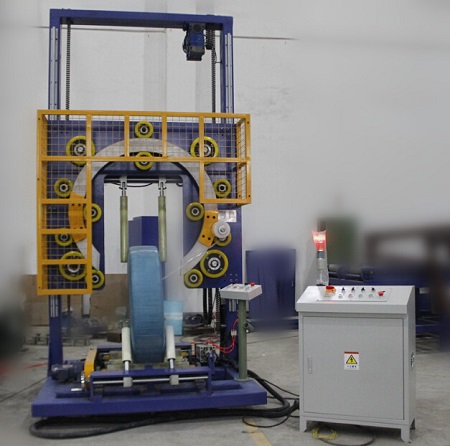

In the fast-paced world of manufacturing and logistics, efficiency and reliability are paramount. This is especially true when it comes to handling materials like steel wire, where the choice of packing machinery can significantly impact productivity. The steel wire packing machine is a critical component that requires careful consideration to ensure seamless operations. But what exactly should businesses look for in a steel wire packing machine? Let’s unravel the essential features.

When it comes to selecting a steel wire packing machine, understanding the specific requirements of your operation is crucial. From speed and durability to automation capabilities, various factors play a role in determining the ideal machine for your business. This article delves into these factors, providing a comprehensive guide to aid your decision-making process.

To thoroughly explore the key features, we first need to connect the dots between the demand for efficient packing solutions and the technological advancements in the industry. This transition will help set the stage for a deeper understanding of what a modern steel wire packing machine can offer.

Claim: Choosing the right steel wire packing machine is vital to boosting your business’s operational efficiency and reducing overhead costs.

What Are the Essential Features of a Steel Wire Packing Machine?

1.1 Speed and Efficiency: Why Do They Matter?

Speed and efficiency are at the heart of any industrial operation. In the context of steel wire packing, these features ensure that production lines keep moving without bottlenecks. A high-speed packing machine can drastically reduce packing time, allowing for more wire to be processed within a given period. This is crucial for businesses looking to scale operations or meet increasing demand.

1.2 Performance Metrics: How Does the Machine Measure Up?

When evaluating a machine's performance, companies should look at numerical data such as packing speed (measured in meters per minute) and downtime reduction. Below is a table outlining potential benchmarks:

| Feature | Benchmark |

|---|---|

| Packing Speed | 300 meters/min |

| Downtime Reduction | 20% |

1.3 Technological Advancements: How Are They Enhancing Performance?

With the rise of Industry 4.0, machines are now equipped with advanced sensors and IoT capabilities. These technologies allow for real-time monitoring and predictive maintenance, minimizing disruptions and extending the lifespan of the equipment. Such advancements significantly contribute to maintaining high levels of productivity and efficiency in the packing process.

1.4 Durability and Maintenance: What Should You Expect?

The robustness of a steel wire packing machine determines its ability to withstand the rigors of daily use. Machines crafted from high-grade materials not only last longer but also require less frequent maintenance. This results in lower operational costs over time. Consider the following data:

| Durability Factor | Expected Lifespan (Years) |

|---|---|

| High-grade Material | 15-20 |

| Standard Material | 5-10 |

1.5 Two-Fact Statement: The Realities of Machine Features

Fact 1 (True): High-speed packing machines can increase productivity by over 30%, allowing for greater throughput. Fact 2 (False): All steel wire packing machines require daily maintenance checks to function correctly. Regular maintenance is essential, but the frequency depends on the specific machine and its usage.

How Do Automation and Customization Influence Machine Selection?

2.1 The Role of Automation: How Does It Transform Operations?

Automation is revolutionizing the manufacturing sector by enhancing precision and reducing labor costs. A steel wire packing machine with automated features can offer programmable settings for different wire types, leading to improved consistency and reduced human error.

2.2 Customization Needs: What Are the Options?

Customization allows businesses to tailor machines to their specific requirements. Whether it’s adjusting the wrapping tension or selecting different wrapping materials, the ability to customize ensures that the machine aligns perfectly with operational needs. Consider these customizable features:

| Customizable Feature | Options Available |

|---|---|

| Wrapping Tension | Variable |

| Material Choice | Plastic, Paper, Metal |

2.3 Advanced Automation: How Does It Differ from Basic Automation?

Advanced automation involves integrating AI and machine learning algorithms that enable machines to adapt to varying conditions and optimize performance autonomously. This level of sophistication further reduces human intervention, freeing up resources and increasing throughput.

2.4 Conclusion: Actionable Insights and Takeaways

When selecting a steel wire packing machine, businesses should evaluate both the technical capabilities and the adaptability to specific operational needs. Identifying the right balance between speed, durability, and automation can lead to significant gains in efficiency and cost-effectiveness.

Conclusion: Selecting a steel wire packing machine is a decision that can greatly influence a business’s operational success. By focusing on key features such as speed, durability, automation, and customization, companies can optimize their processes and achieve competitive advantages. Claim: Investing in the right packing machine is an investment in your business’s future efficiency and profitability.