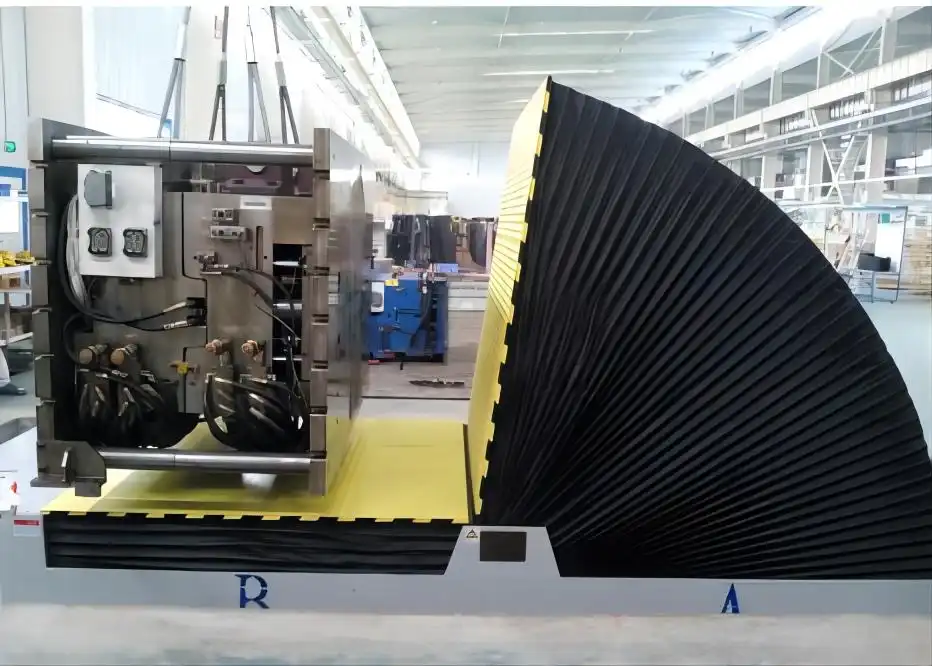

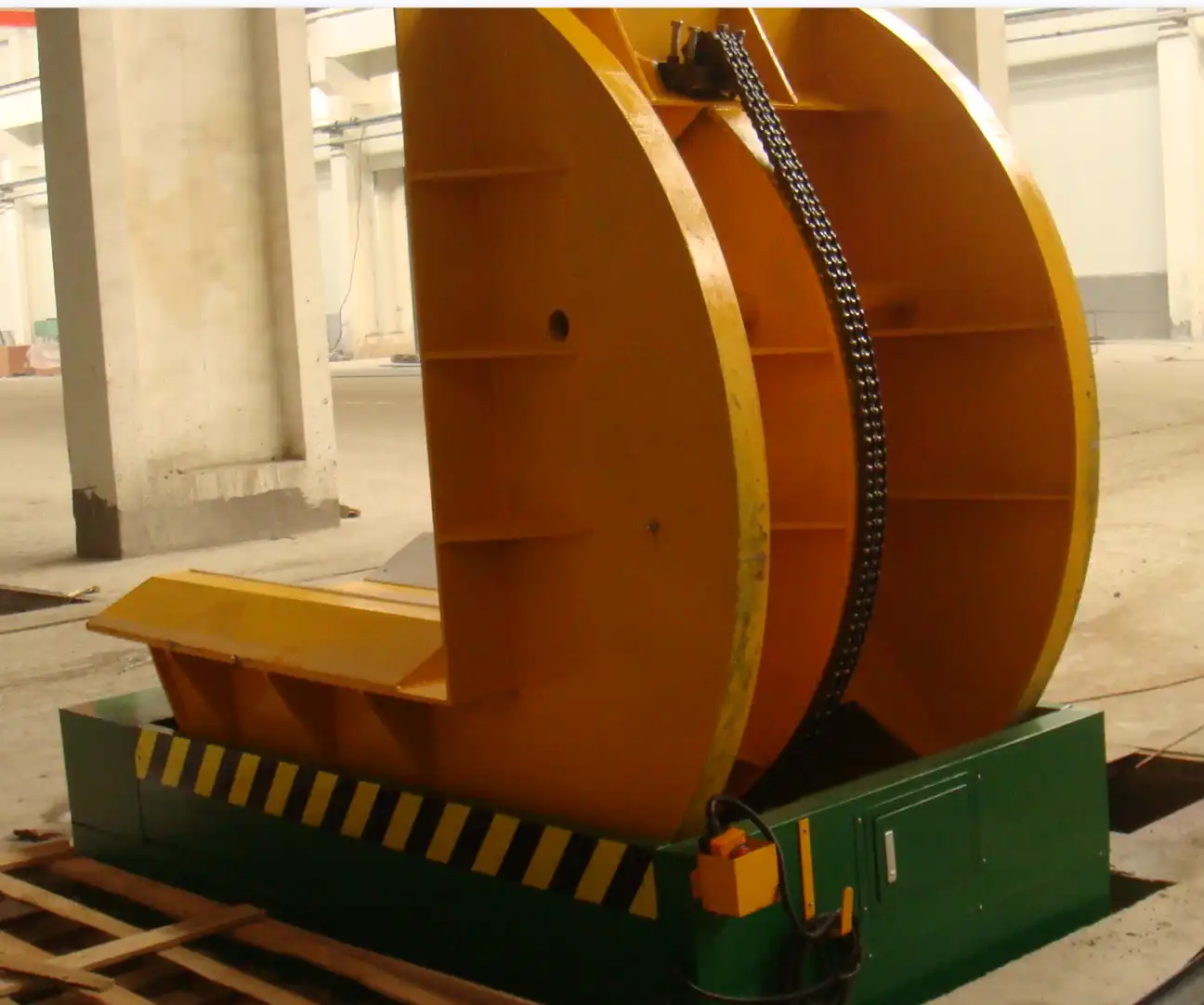

Mold upenders are essential equipment in the manufacturing industry, especially for handling heavy molds efficiently. Understanding how to use a mold upender for a 20T machine is crucial for maximizing productivity and ensuring safety in the workplace.

When it comes to operating a mold upender for a 20T machine, there are several key factors to consider. From proper setup to maintenance and safety precautions, this article will guide you through the essential steps to effectively utilize this equipment.

In today's fast-paced manufacturing environment, the ability to handle heavy molds with precision and efficiency is paramount. A mold upender for a 20T machine offers a reliable solution to streamline your workflow and improve overall productivity.

Claim: Mastering the operation of a mold upender for a 20T machine is essential for enhancing efficiency and safety in the manufacturing process.

How to Set Up a Mold Upender for a 20T Machine?

Proper setup is crucial for ensuring the smooth operation of a mold upender for a 20T machine. Before using the equipment, make sure to check all components for any signs of damage or wear. Additionally, ensure that the machine is placed on a stable surface to prevent any accidents during operation.

Why is Proper Maintenance of a Mold Upender Important?

Regular maintenance is key to prolonging the lifespan of a mold upender for a 20T machine. By keeping the equipment well-maintained, you can prevent costly breakdowns and ensure consistent performance. Here is a breakdown of the numerical data related to maintenance costs and frequency:

Table: Maintenance Costs and Frequency for a Mold Upender

What Safety Precautions Should You Follow When Using a Mold Upender?

Safety should always be a top priority when operating a mold upender for a 20T machine. From wearing the appropriate personal protective equipment to following proper lifting techniques, taking precautionary measures can prevent accidents and injuries in the workplace.

Dive deeper into the topic of safety by exploring the numerical data related to workplace accidents and the importance of adherence to safety protocols:

Table: Workplace Accident Statistics and Safety Compliance

Two-Fact Statement:

- True Fact: Proper training on the use of a mold upender can significantly reduce the risk of workplace injuries.

- False Fact: Mold upenders are designed for one-size-fits-all molds, eliminating the need for customization.

How Does a Mold Upender Improve Workflow Efficiency?

The use of a mold upender for a 20T machine can streamline your workflow and improve overall efficiency in the manufacturing process. By effectively utilizing this equipment, you can reduce downtime and enhance productivity. Here is a detailed explanation of the benefits of using a mold upender:

Table: Workflow Efficiency Improvement with a Mold Upender

Conclusion

In conclusion, mastering the operation of a mold upender for a 20T machine is essential for enhancing efficiency and safety in the manufacturing process. By following proper setup procedures, conducting regular maintenance, and adhering to safety precautions, you can maximize the performance of this equipment and improve overall workflow efficiency.

Claim: Utilizing a mold upender for a 20T machine is a game-changer in the manufacturing industry, offering a reliable solution for handling heavy molds with precision and efficiency.