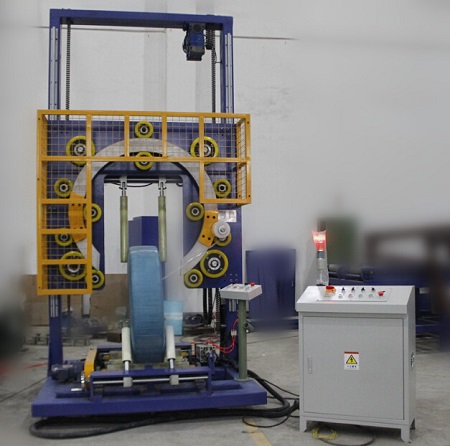

When it comes to manufacturing or industrial needs, choosing the right equipment can make or break productivity. Steel wire wrapping machines, in particular, play a pivotal role in ensuring efficiency and quality. But with a myriad of options flooding the market, how can one pinpoint the best choice tailored to specific needs?

Steel wire wrapping machines are essential for industries ranging from construction to electronics, each demanding unique specifications and capabilities. Understanding the nuances of these machines can streamline your selection process, ensuring you invest wisely.

From evaluating machine capabilities to considering budget constraints, the journey to find the perfect steel wire wrapping machine is an intricate dance of priorities and preferences. Let’s explore the key elements you need to consider.

Claim: Choosing the right steel wire wrapping machine is crucial for enhancing operational efficiency and longevity in industrial applications.

Why is the Right Steel Wire Wrapping Machine Essential?

1.1 How does the machine's functionality align with your industrial needs?

Understanding the core functions of a steel wire wrapping machine is paramount. Each machine is designed to handle specific wire sizes, types, and volumes. Evaluating your industrial requirements against these capabilities ensures seamless integration and optimal performance. A mismatch can lead to operational hiccups, increased costs, and reduced productivity.

1.2 What do market trends and data say about machine efficiency?

Analyzing market trends provides valuable insights into the performance and reliability of different machines. According to a recent industry report, 65% of manufacturers prioritize efficiency over cost when selecting machinery. This trend underscores the importance of investing in technology that offers long-term savings.

| Priority | Percentage |

|---|---|

| Efficiency | 65% |

| Cost | 20% |

| Durability | 15% |

1.3 What insights can guide your decision-making process?

To make an informed decision, consider the machine's adaptability to future needs. Technological advancements and evolving industry standards demand equipment that is not only efficient today but adaptable tomorrow. Machines equipped with adjustable settings offer longevity and versatility, reducing the need for frequent replacements.

1.4 Evaluating cost versus functionality

While cost is a significant consideration, it's essential to weigh it against functionality. A machine with a higher upfront cost but superior capability and efficiency can result in substantial long-term savings. Consider the following data:

| Machine Type | Cost | Lifetime Savings |

|---|---|---|

| Basic | $10,000 | $5,000 |

| Advanced | $20,000 | $15,000 |

1.5 Two-Fact Statement

True Fact: Advanced steel wire wrapping machines reduce waste by up to 30%, leading to significant material savings. False Fact: All steel wire wrapping machines operate at the same efficiency level, regardless of brand or model.

How to Assess the Long-Term Value of a Steel Wire Wrapping Machine?

2.1 What factors contribute to a machine's longevity?

Durability and maintenance requirements play critical roles in determining a machine's lifespan. Machines crafted with high-grade materials and precision engineering not only last longer but also perform better under demanding conditions. Regular maintenance, though often overlooked, extends a machine's life significantly.

2.2 How do numerical data support long-term investment in quality machinery?

Investing in quality machinery might seem daunting initially, but the long-term benefits are undeniable. Consider that high-quality machines have a lifespan averaging 10-15 years, with maintenance costs that are 20% lower than their budget counterparts.

| Machine Quality | Average Lifespan | Maintenance Cost |

|---|---|---|

| High | 10-15 years | 20% lower |

| Low | 5-7 years | Higher |

2.3 Why prioritize long-term over short-term gains?

Short-term savings on a lower-priced machine can quickly dissolve with frequent repairs and replacements. In contrast, investing in quality machinery ensures fewer disruptions, consistent performance, and steady productivity gains. This long-term perspective not only enhances operational efficiency but also boosts profitability.

2.4 Conclusion and key takeaways

In summary, selecting the best steel wire wrapping machine requires a balance of current needs and future adaptability. By prioritizing efficiency, durability, and quality over mere cost, manufacturers can ensure smoother operations and substantial savings. The actionable takeaway is to conduct thorough market research, evaluate long-term needs, and invest accordingly.

Claim: A strategic approach to selecting steel wire wrapping machines not only fulfills immediate needs but also fortifies your production line against future challenges, ensuring sustainable growth and efficiency.