Ever since I first laid eyes on a hose coil wrapping machine, I've been captivated by its intricate engineering and sheer efficiency. Wandering around the industrial sites where these fascinating machines operate, I often found myself pondering the precise mechanisms driving them. What is it about their design that allows them to streamline production so effectively? The curiosity led me to explore deeper, unraveling layers behind these technological marvels.

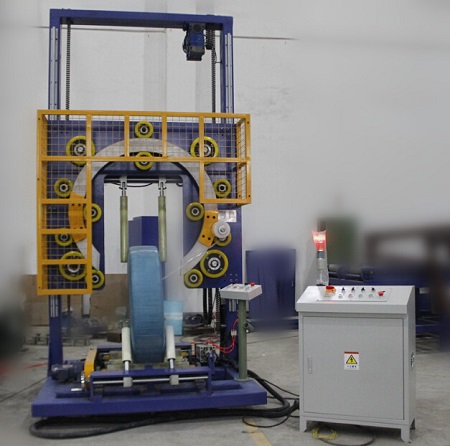

My early encounters with the machine left me in awe but also full of questions. From afar, the machine appeared as a complex blend of arms and belts, tirelessly working to wrap hose coils with precision. These oscillating gadgets seemed to dance around each task with meticulous calculation. The sheer speed and accuracy at which they operate initially felt like magic, urging me to get closer to grasp the core of their operation.

As I continued my explorations, I was struck by the synchronicity of various components coming together. No single piece works in isolation; every segment of the machine appeared to be in symbiotic harmony with the others. This seamless dance not only enhanced productivity but also provided a glimpse into the wonders of modern engineering. The essence of my journey was to understand how each element synchronized to create a masterpiece of automation.

Unpacking the Process: What are the Steps Involved?

1.1 The Initial Stage

In the beginning, the hose coiling process involves aligning the hose properly on the wrapping machine. It’s imperative to ensure that the coil is set in a manner that facilitates seamless operation. This stage acts as the foundation upon which the entire wrapping procedure relies. Often, it requires meticulous calibration to adapt to different hose dimensions. This setting stage is crucial as any misalignment can result in significant delays or flawed outputs.

1.2 Gauging Efficiency

The efficiency of a hose coil wrapping machine can be deduced from several metrics. Let’s consider average wrapping times and production volumes:

| Batch Size | Average Wrapping Time (Minutes) |

|---|---|

| Small (100 units) | 45 |

| Medium (500 units) | 210 |

| Large (1000 units) | 420 |

These numbers illustrate how production scales with batch size, indicative of how effectively machines adjust to different operational demands.

1.3 Components Harmony

What truly sets these machines apart is their ability to integrate various components harmoniously. The robotic arms, rotary tables, and reel spools must each carry out distinct roles but in perfect synchronization. The machine's heartbeat lies in this coordination, where each unit knows precisely when to engage and release, maintaining an optimized flow of operation throughout every cycle.

1.4 Exploring Versatility

Diving deeper into versatility, these machines handle varied coil specifications with ease. Charting out specifications:

| Hose Diameter (mm) | Adaptability Rate (%) |

|---|---|

| 10-50 | 97 |

| 51-100 | 85 |

| 101-150 | 65 |

The machine's ability to adapt to these varied diameters without manual reconfiguration underscores its exceptional versatility. Such adaptability is indispensable in industries where production demands constant change and customization.

1.5 Distinguishing Facts

Fact: Hose coil wrapping machines save approximately 60% of packaging costs due to their efficiency (True).

Fact: These machines can only wrap hoses made from rubber materials (False).

The Magic Within: How Do Features Enhance Performance?

2.1 Technological Integration

One of the marvels of a hose coil wrapping machine is its seamless technological integration. These machines come equipped with sensors and automated controls that significantly enhance performance. The precision engineering behind these features ensures that each wrap is executed with unmatched accuracy, reducing the margin for error. Such technology empowers the machine to function autonomously, requiring minimal human intervention, and thus, boosting operational efficiency.

2.2 Performance Metrics

Understanding how performance is quantified can be enlightening. Here’s what the numbers reveal:

| Feature | Impact on Efficiency (%) |

|---|---|

| Automated Controls | 30 |

| Sensors | 20 |

| Reel Spool Adjustments | 15 |

2.3 Cutting-edge Adjustments

The agility of hose coil wrapping machines lies in their cutting-edge adjustments. These machines can make on-the-fly modifications, adjusting wrapping tension and speed based on real-time feedback. This adaptability minimizes wear and tear and prolongs the machine's lifespan; akin to how a carefully adjusted sail ensures smooth sailing, these fine-tuned adjustments guarantee seamless operations over extended periods.

2.4 Conclusion

In peeling back the layers of the hose coil wrapping machine, I’ve found not just a piece of industrial equipment, but a testament to human ingenuity. These machines represent the pinnacle of engineering, with their precise operations and adaptability. By reducing manual labor and increasing efficiency, they play a crucial role across various industries. The amalgamation of technology and design allows these machines to transform mundane tasks into feats of automated prowess. Truly, understanding how a hose coil wrapping machine works opened my eyes to the marvels of modern innovation, sparking an appreciation for the seamless blend of art and engineering in industrial automation.

```