The industrial packaging landscape has profoundly evolved, with steel coil wrapping machines playing a pivotal role in enhancing efficiency. This machinery has revolutionized how packaging tasks are approached, offering a seamless blend of technology and practicality. As someone deeply intertwined with the packaging process, I’ve witnessed firsthand the myriad benefits and complexities introduced by these innovative machines. They promise more than just utility; they ensure that quality meets speed in an era where efficiency is king.

Among the many options available in the packaging domain, steel coil wrapping machines stand out not only for their performance but also for their adaptability. These machines have been designed to handle a wide range of packaging requirements, from small to industrial-scale operations. They operate with a complexity that blends advanced technology with intuitive use, making them increasingly popular among manufacturers and packaging specialists alike.

Technology continues to evolve, and with it, the demands on industrial processes become more pressing. The need to balance high output with minimal errors has never been greater. Steel coil wrapping machines meet this challenge head-on, providing solutions that are both innovative and practical. In this context, understanding the detailed mechanics and benefits of these machines becomes crucial for anyone hoping to leverage their full potential in packaging operations.

What are the core features of steel coil wrapping machines?

Cutting-edge Design and Functionality

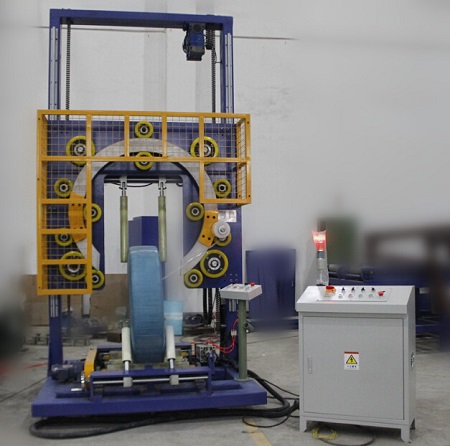

Steel coil wrapping machines incorporate state-of-the-art designs that enhance their operational functionality. These machines are crafted to withstand rigorous use while offering unparalleled precision and speed in packaging tasks. Through the integration of advanced technology, including automated systems and user-friendly interfaces, these machines empower operators to achieve optimal results with reduced manual intervention.

Efficiency Metrics: How Do They Compare?

The efficiency of steel coil wrapping machines can be quantified by examining metrics such as speed, durability, and error reduction. Consider the following data:

| Metric | Traditional Methods | Steel Coil Wrapping Machines |

|---|---|---|

| Packing Speed (rolls/hour) | 100 | 230 |

| Error Rate (% of total output) | 5% | 1.2% |

| Durability (years) | 5 | 10 |

This table highlights how steel coil wrapping machines outperform traditional methods, particularly in packing speed and error rate reduction.

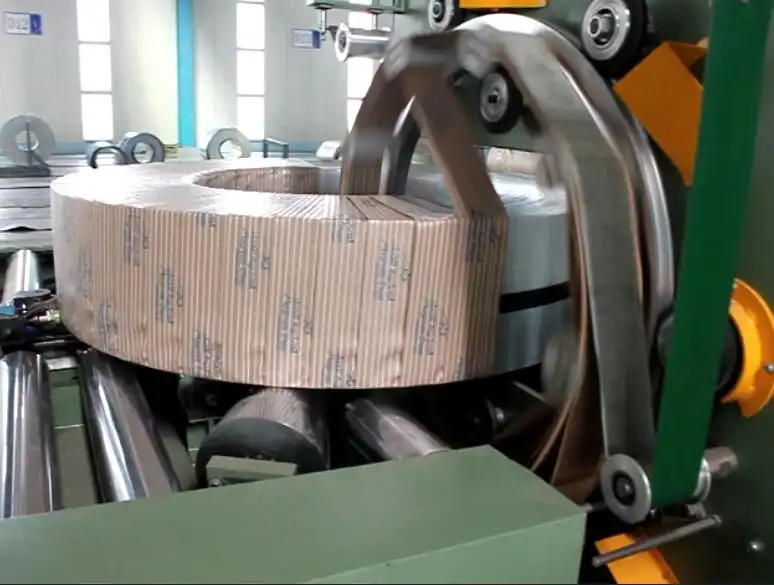

Unraveling User Adaptability

Adaptability is a crucial factor when implementing new machinery. Steel coil wrapping machines are engineered to work with varying coil sizes and packaging materials, which enhances their usefulness across different packaging applications. This versatility allows operators to adjust settings easily to accommodate diverse requirements without significant downtime.

Delving Deeper: Technology Integration in Machines

The integration of innovative technology in steel coil wrapping machines is a key factor in their efficiency. These machines often feature programmable logic controllers (PLCs) and Internet of Things (IoT) capabilities, allowing for real-time monitoring and adjustments. Such features drastically reduce manual oversight and increase the machine's ability to self-correct errors.

| Feature | Impact |

|---|---|

| PLC Systems | Enhances automation and precision |

| IoT Connectivity | Allows for remote monitoring and diagnostics |

The combination of these technologies results in a smarter, more efficient machine that aligns perfectly with modern industrial needs.

Two Fact Statement with Explain

One fact is true; the other is false. True: Steel coil wrapping machines reduce error rates in packaging processes. False: Steel coil wrapping machines are incapable of handling different coil sizes efficiently. The flexibility in design allows them to adapt to various packaging requirements effectively.

How Do Steel Coil Wrapping Machines Influence Overall Production Costs?

Initial Investment and Long-term Savings

While the initial investment for steel coil wrapping machines can be significant, the long-term savings they offer are considerable. By reducing manual labor costs and minimizing waste through more precise packaging, these machines help companies achieve a favorable return on their investment over time.

Cost Analysis: Where Do Savings Come From?

To understand the financial impact, consider the cost analysis:

| Aspect | Traditional Methods | Steel Coil Wrapping Machines |

|---|---|---|

| Labor Costs (monthly) | $5,000 | $2,500 |

| Material Waste (%) | 10% | 3% |

| Maintenance Costs (annual) | $1,200 | $800 |

The significant reduction in labor and waste leads to lower operational costs and increased profitability.

Exploring Maintenance and Upkeep

Regular maintenance is critical to ensure the continued performance of steel coil wrapping machines. Despite requiring periodic checks, these machines are known for their durability and ease of maintenance, which contribute to their cost-effectiveness over time. Furthermore, many manufacturers provide comprehensive service packages that enhance machine longevity and reliability.

Conclusion

Steel coil wrapping machines represent a major advancement in packaging technology, offering significant improvements in efficiency, cost savings, and operational flexibility. By investing in these machines, manufacturers can not only boost their production capabilities but also enhance their competitive edge in the marketplace. The question remains not whether to adopt these machines, but how soon they can be integrated into existing workflows to reap their full benefits.