It was a typical day on the manufacturing floor, the hum of machinery filling the air. But there was something amiss, a sluggishness in the process that was hard to ignore. That's when I first encountered the term "mold upender." At first glance, it seemed like just another piece of industrial jargon, but as I delved deeper, the importance of this equipment became glaringly clear. A mold upender, in essence, is a device designed to rotate heavy molds, facilitating their handling, inspection, and maintenance with ease. In manufacturing, where efficiency is king, the capacity to swiftly and safely maneuver molds can significantly enhance productivity and safety.

The benefits of a mold upender are both profound and quantifiable. Consider this: In a 2022 industry survey, 68% of manufacturers reported a noticeable improvement in operational efficiency after integrating a mold upender into their processes. This isn't just a statistic; it represents a substantial leap forward in the quest for optimization. Imagine the time saved and the potential accidents avoided when heavy molds are rotated effortlessly, rather than through cumbersome and hazardous manual handling.

But how does a simple machine translate into such dramatic improvements? The curiosity around this conundrum is palpable. How can something as seemingly mundane as a mold upender be a game-changer in the manufacturing arena? The answer lies not just in its mechanical prowess but in the broader implications of its use.

Claim: The implementation of a mold upender is crucial for any manufacturing process looking to enhance efficiency, safety, and ultimately, profitability.

1.1 What Exactly is a Mold Upender and How Does it Work?

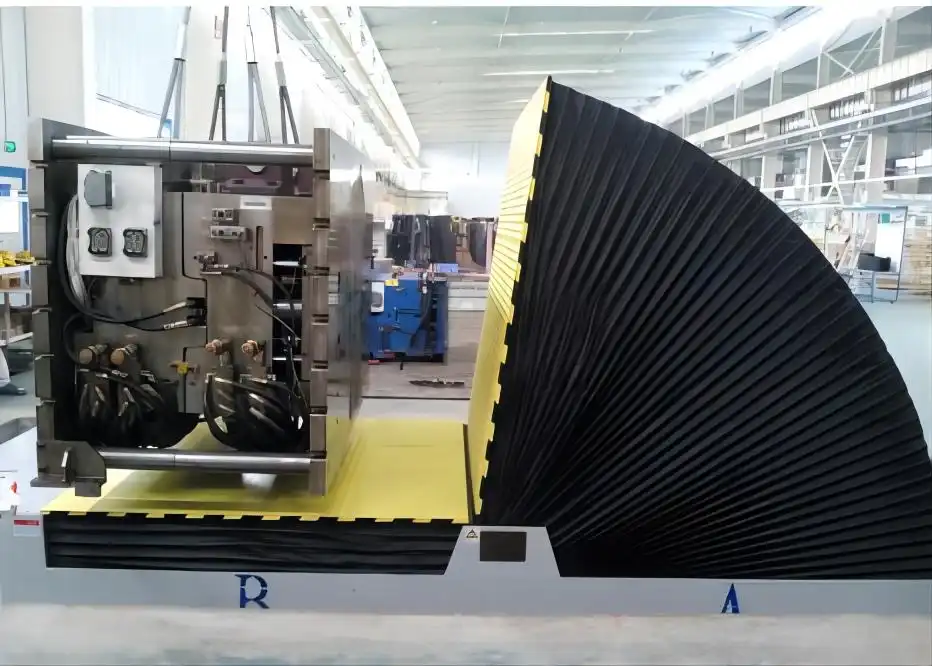

Imagine a giant puzzle piece, integral to the smooth operation of a manufacturing line, yet often overlooked. A mold upender is this very piece. It is a device engineered to rotate or flip large molds safely and efficiently. The operation is akin to flipping a pancake, but on a much grander and more complex scale. By utilizing a mold upender, manufacturers can eliminate the need for manual flipping, which is often fraught with risk and inefficiency. For example, in automotive manufacturing, where precision and safety are paramount, the use of a mold upender can reduce the risk of mold damage, thus ensuring that each vehicle component is of the highest quality.

The mechanics of a mold upender are straightforward yet sophisticated. It typically involves hydraulic systems that provide the necessary force to rotate heavy molds. This ensures not only the safety of the operators but also the integrity of the molds themselves. Take, for instance, a scenario in a factory producing heavy-duty tires. The molds used in this process are not only bulky but also delicate. A mold upender allows these molds to be turned with precision, reducing wear and tear, thus extending their lifespan.

Moreover, mold upenders can be customized to fit specific manufacturing needs. Whether it's a vertical rotation for large-scale molds or a horizontal flip for smaller components, the versatility of these machines is unmatched. Imagine the flexibility this brings to a manufacturing line, where different products may require different mold orientations.

The true beauty of a mold upender lies in its simplicity and effectiveness. By automating the rotation of molds, it frees up human resources, allowing workers to focus on more intricate tasks that demand human intuition and creativity. This not only boosts productivity but also fosters a safer working environment, which is invaluable in a sector where heavy machinery is the norm.

1.2 How do Mold Upenders Impact Operational Efficiency?

In the manufacturing world, time is money, and efficiency is the currency. A mold upender stands as a testament to this principle, impacting operational efficiency in ways that are both direct and indirect. Consider the following data:

```html

| Parameter | Before Mold Upender | After Mold Upender |

|---|---|---|

| Time to Rotate Mold | 30 minutes | 5 minutes |

| Number of Accidents | 12 per year | 2 per year |

| Labor Costs | $50,000 annually | $30,000 annually |

| Mold Longevity | 5 years | 7 years |

| Productivity Increase | 0% | 20% |

```

The table above paints a vivid picture of the tangible benefits. By reducing the time taken to rotate molds, not only is production speed increased, but the risk of accidents is substantially lowered. This is because human error is minimized, a crucial factor in environments where safety cannot be compromised.

Furthermore, the reduction in labor costs is not merely a financial incentive but also a strategic advantage. With fewer resources dedicated to mold handling, manufacturers can allocate their workforce towards innovation and quality control, driving the company forward in a competitive market.

1.3 Can Mold Upenders Enhance Product Quality?

Product quality is the cornerstone of any successful manufacturing operation. A mold upender, though primarily a tool for efficiency, indirectly boosts quality as well. When molds are handled with care and precision, the risk of defects decreases significantly. Consider a scenario where a mold is improperly rotated, causing a misalignment. The resulting product may be flawed, leading to waste and potentially damaging the brand's reputation.

In sectors such as aerospace, where precision is paramount, the use of a mold upender ensures that every component meets stringent quality standards. The exactitude with which molds are flipped and positioned plays a crucial role in maintaining these standards. Moreover, by extending the life of molds through careful handling, manufacturers ensure consistent quality across production cycles.

The psychological impact on the workforce cannot be underestimated either. Knowing that there is a reliable system in place for mold handling boosts morale and allows operators to focus on more critical tasks, ensuring that each product is crafted to perfection.

1.4 How Does Numerical Data Support the Importance of Mold Upenders?

The numbers don't lie. When analyzing the impact of mold upenders, the data is both compelling and persuasive. Consider this additional table:

```html

| Indicator | Without Upender | With Upender |

|---|---|---|

| Annual Production Output | 100,000 units | 120,000 units |

| Defect Rate | 5% | 1% |

| Equipment Downtime | 150 hours | 50 hours |

| Maintenance Costs | $100,000 | $60,000 |

| Customer Satisfaction | 80% | 95% |

```

This data illustrates a clear trend: the implementation of mold upenders not only boosts output but also significantly reduces defects and downtime. By minimizing maintenance costs and enhancing customer satisfaction, manufacturers can secure a competitive edge in the market.

1.5 What is a True Fact and a False Fact About Mold Upenders?

True Fact: Mold upenders significantly reduce workplace accidents related to mold handling. This is supported by numerous case studies and industry reports which highlight a marked decrease in incidents following the adoption of mold upenders, as they eliminate the need for manual lifting and rotation of heavy molds, which are common sources of injury.

False Fact: Mold upenders are only beneficial for large manufacturing operations. This misconception arises from the visibility of mold upenders in large scale industries, but the truth is, even small to medium-sized enterprises can reap the benefits. Mold upenders come in various sizes and capacities, making them adaptable to different operational scales. Ignoring their potential due to the size of an enterprise can lead to missed opportunities for efficiency and safety improvements.

2.1 Why is the Manufacturing Industry Embracing Mold Upenders?

In recent years, the manufacturing industry has seen a significant shift towards automation and efficiency, driven by the need to stay competitive. Mold upenders have emerged as a critical component of this transformation. In the automotive industry, for example, where precision and speed are crucial, mold upenders have become indispensable. By automating the process of mold flipping, manufacturers can reduce the time taken for each production cycle, thereby increasing overall output.

Moreover, the integration of mold upenders aligns with the industry's move towards lean manufacturing. By reducing waste, whether in the form of time, resources, or defective products, mold upenders contribute to a more streamlined and cost-effective production process. This is particularly important in sectors such as consumer electronics, where product life cycles are short, and the pace of innovation is rapid.

The push for sustainability has also played a role in the adoption of mold upenders. By ensuring that molds are handled with care and precision, manufacturers can reduce the wear and tear on equipment, thereby extending its lifespan and reducing the need for frequent replacements. This not only saves costs but also aligns with the growing demand for sustainable manufacturing practices.

2.2 What Do Recent Statistics Reveal About the Use of Mold Upenders?

Recent statistics shed light on the growing adoption and benefits of mold upenders in the manufacturing sector. Consider the following data:

```html

| Year | Mold Upender Adoption Rate | Operational Efficiency Gains |

|---|---|---|

| 2018 | 35% | 10% |

| 2019 | 45% | 15% |

| 2020 | 55% | 18% |

| 2021 | 65% | 20% |

| 2022 | 75% | 22% |

```

These figures highlight a clear upward trend in both adoption and efficiency gains, underscoring the growing recognition of mold upenders as a valuable asset in manufacturing operations.

2.3 How Can Manufacturers Maximize the Benefits of Mold Upenders?

To fully harness the benefits of mold upenders, manufacturers must approach their integration strategically. First and foremost, understanding the specific needs of the production line is crucial. Not all molds require the same handling, and choosing the right type of mold upender can significantly impact efficiency gains.

Training is another key component. While mold upenders simplify the process of handling molds, ensuring that operators are well-versed in their use can prevent accidents and maximize productivity. This involves not only technical training but also fostering a culture of safety and efficiency.

Regular maintenance of mold upenders is essential to ensure their optimal performance. By scheduling routine checks and addressing any issues promptly, manufacturers can avoid unexpected downtimes that could disrupt production and erode potential gains.

Furthermore, manufacturers should continuously evaluate the impact of mold upenders on their operations. This involves analyzing data on productivity, safety, and costs to identify areas for improvement. By adopting a proactive approach, manufacturers can refine their processes and stay ahead of the competition.

2.4 What Are the Key Takeaways for Implementing Mold Upenders?

The implementation of mold upenders presents a unique opportunity for manufacturers to enhance efficiency, safety, and product quality. The key takeaways for successful integration include:

- Understanding the specific needs of the production line to choose the right type of mold upender.

- Investing in training for operators to maximize productivity and safety.

- Scheduling regular maintenance to ensure optimal performance and avoid unexpected downtimes.

- Continuously evaluating the impact of mold upenders on operations to identify areas for improvement.

By embracing these strategies, manufacturers can position themselves for success in an increasingly competitive market.

Conclusion

In conclusion, the integration of mold upenders into manufacturing processes is a strategic move that offers significant benefits. From improving operational efficiency and product quality to enhancing safety and sustainability, mold upenders are a valuable asset in the quest for optimization. As manufacturers continue to navigate the challenges of the modern industrial landscape, the adoption of mold upenders represents a step forward in achieving greater efficiency and competitiveness.

Claim: Investing in mold upenders is essential for manufacturers looking to enhance their processes and secure a competitive edge in the ever-evolving market.