In the bustling world of industrial equipment, selecting the right tools can make or break an operation. Among these pivotal decisions is choosing the ideal pipe coil wrapping machine. This piece of machinery, though specialized, plays a crucial role in ensuring the efficiency and productivity of packaging processes. But what exactly should one consider when making this significant investment?

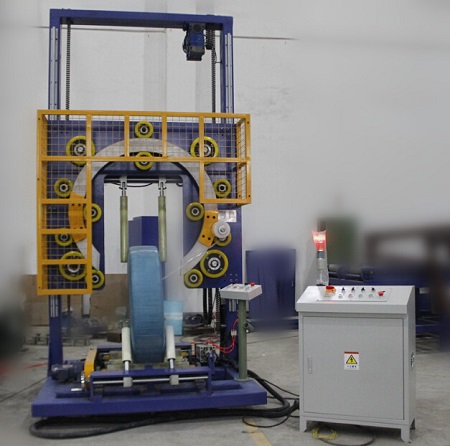

Pipe coil wrapping machines are intricate devices, designed to protect and transport pipes safely by encasing them in protective materials. With a myriad of options available, buyers often find themselves overwhelmed by technical specifications and sales pitches. Understanding the core elements that matter most can simplify the selection process.

The journey to finding the perfect pipe coil wrapping machine can be daunting. It's not just about price or brand; it's about aligning the machine’s capabilities with your specific operational needs. Let's delve deeper into the essential factors that should influence your decision-making process.

Claim: Choosing the right pipe coil wrapping machine is imperative for operational efficiency and product protection in industrial packaging.

What are the Key Features to Look for in a Pipe Coil Wrapping Machine?

1.1 Understanding Your Operational Needs

Before diving into the specifications of pipe coil wrapping machines, it's crucial to assess your operation's unique demands. What types of pipes are you wrapping? How frequently will the machine be in use? Answering these questions will guide you toward a machine that aligns with your production requirements, ensuring optimal performance without unnecessary expenditure.

1.2 Efficiency and Speed: A Numerical Perspective

| Machine Model | Wrapping Speed (coils/hour) | Power Consumption (kW) |

|---|---|---|

| Model A | 15 | 5 |

| Model B | 20 | 7 |

| Model C | 18 | 6 |

Efficiency is key in any production environment. As the table above illustrates, the speed of wrapping and power consumption are vital metrics. Model B, for instance, wraps 20 coils per hour, making it an excellent choice for high-volume operations despite its higher power consumption.

1.3 Customization Options for Diverse Needs

Not all pipe coil wrapping machines are created equal. Some offer extensive customization options, allowing operators to adjust settings to cater to different pipe sizes and materials. This flexibility is essential for operations dealing with a variety of products, ensuring the machine can adapt to changing demands.

1.4 Delving Deeper into Machine Capabilities

| Capability | Model A | Model B | Model C |

|---|---|---|---|

| Max Pipe Diameter (mm) | 500 | 600 | 550 |

| Film Type Compatibility | Polyethylene, PVC | PVC, Polyolefin | Polyethylene, Polyolefin |

Understanding the machine's capabilities helps in determining its fit for your operations. Model B, for instance, accommodates larger pipe diameters and diverse film types, offering versatility but at a potentially higher cost.

1.5 Two-Fact Statement

True: A high-speed pipe coil wrapping machine can significantly reduce labor costs by increasing efficiency. False: All pipe coil wrapping machines offer the same level of customization; in reality, features vary greatly among models.

How Do Cost and Maintenance Influence Your Decision?

2.1 Weighing Cost Against Value

Cost is a primary consideration for any business acquisition, yet it's essential to evaluate the value the machine brings. A lower upfront cost might be attractive, but if it results in higher maintenance expenses or inefficiencies, the savings quickly dwindle. Look for a balance that delivers long-term value.

2.2 Maintenance and Operational Costs

| Machine Model | Maintenance Cost (annually) | Operational Cost (per hour) |

|---|---|---|

| Model A | $500 | $3 |

| Model B | $700 | $4.5 |

| Model C | $600 | $4 |

The table highlights how ongoing maintenance and operational costs vary between models. While Model A has the lowest maintenance cost, its operational cost is competitive, making it a viable option for cost-conscious businesses.

2.3 Long-Term Investment and Reliability

Opting for a reputable brand with a proven track record can reduce long-term risks. Reliable machines often come with higher price tags but offer peace of mind through durability and consistent performance, reducing downtime and enhancing productivity.

2.4 Conclusion: Making an Informed Purchase

When selecting a pipe coil wrapping machine, consider not just the immediate needs but also future scalability. Evaluate how the machine will integrate into your existing processes and the potential return on investment it offers through efficiency gains and cost savings.

Conclusion: Selecting the right pipe coil wrapping machine involves balancing operational demands, cost, and long-term benefits. By understanding your needs and evaluating machine capabilities, you can make an informed decision. Claim: Investing in a high-quality, efficient pipe coil wrapping machine enhances operational efficiency and safeguards product integrity, ensuring seamless industrial packaging processes.