```html

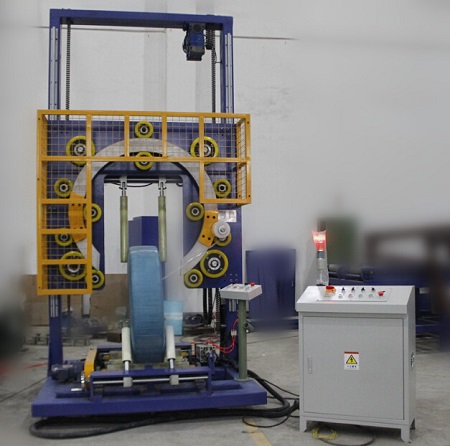

In the bustling world of industrial machinery, steel wire packing machines stand as titans of efficiency and productivity. These machines are vital in ensuring that steel wires are packaged neatly and securely, ready for distribution. However, like all mechanical devices, they require meticulous care and attention to maintain their peak performance.

Understanding the nuances of after-sales support and maintenance can dramatically enhance the longevity and efficiency of your steel wire packing machines. By implementing the right strategies, businesses can not only reduce downtime but also prevent costly repairs that might arise from neglected upkeep.

Maintaining these machines isn't just about following a set schedule; it's about understanding their intricate workings and predicting potential issues before they escalate. The following sections will delve into specific maintenance tips and after-sales support practices that can safeguard your investment.

Claim: Prioritizing regular maintenance and leveraging effective after-sales support are crucial for maximizing the lifespan and operational efficiency of steel wire packing machines.

Why is Maintenance Critical for Steel Wire Packing Machines?

1.1 Understanding the Importance of Regular Maintenance

Regular maintenance of steel wire packing machines ensures that they function smoothly without interruptions. By routinely inspecting components, businesses can catch wear and tear early, preventing larger, more expensive issues. This foresight not only saves money but also extends the machine's lifespan.

1.2 The Numbers Behind Machine Maintenance

Studies indicate that regular maintenance can increase machine efficiency by up to 20%. Here's a quick breakdown:

| Maintenance Frequency | Efficiency Improvement |

|---|---|

| Monthly | 10% |

| Quarterly | 15% |

| Annually | 20% |

1.3 Insights on Efficient Maintenance Strategies

To ensure that maintenance efforts are effective, focus on the critical components of the machine. This includes the lubrication of moving parts, checking the tension of belts, and ensuring that sensors are calibrated correctly. By addressing these areas, you minimize the risk of unexpected breakdowns.

1.4 Delving Deeper into Maintenance Protocols

Understanding the technical aspects of your machine can greatly enhance maintenance outcomes. For instance, regularly updating the software used in modern packing machines can improve functionality and efficiency. The table below highlights some critical components to monitor:

| Component | Maintenance Tip |

|---|---|

| Belts and Pulleys | Check for wear and ensure proper tension. |

| Lubrication Points | Regularly apply recommended lubricants. |

| Electronic Controls | Update software periodically for optimal performance. |

1.5 Two-Fact Statement

True: Regular maintenance can increase the lifespan of machinery by up to 25%. This fact highlights the importance of looking after your investment diligently.

False: Maintenance requires replacing all parts annually. In reality, only specific components may need periodic replacements based on usage and wear.

How Can After-Sales Support Enhance Machine Longevity?

2.1 The Role of After-Sales Support

After-sales support is a crucial aspect that companies often overlook. Effective support provides ongoing technical assistance, ensuring your machine continues to deliver optimal performance. This support can be in the form of spare parts supply, troubleshooting assistance, and even training for your staff.

2.2 Quantifying the Impact of After-Sales Support

The importance of robust after-sales support is mirrored in customer satisfaction rates. Research shows that companies with dedicated after-sales services see a 30% increase in customer retention. Consider this breakdown:

| Service Type | Customer Retention Rate |

|---|---|

| Basic Support | 70% |

| Comprehensive Support | 90% |

2.3 Delving into Support Structures

Effective after-sales support encompasses more than just the provision of spare parts. It involves building a relationship with the supplier, receiving regular updates about technological advancements, and having access to expert technicians who can solve complex issues quickly.

2.4 Conclusion

By prioritizing both maintenance and after-sales support, businesses can significantly enhance the efficiency and lifespan of their steel wire packing machines. It’s about creating a holistic approach that covers all aspects of machine care, ensuring peace of mind and uninterrupted operations.

Conclusion: A robust maintenance regime, coupled with comprehensive after-sales support, is indispensable for businesses relying on steel wire packing machines. Maintaining these practices not only boosts operational efficiency but also secures a high return on investment. Claim: Investing in effective after-sales support services is as crucial as the initial purchase for ensuring continued machine performance and reliability.

```