I've always found myself fascinated by machinery that combines complexity with utility. Steel coil wrapping machines, in particular, hold a unique allure, with their intricate designs and essential role in industries worldwide. It all started when I first stepped into a vast warehouse filled with these powerful machines whirring rhythmically, going about their purpose with unparalleled precision.

Among the vast array of machinery designed to cater to different industrial needs, steel coil wrapping machines stand out due to their critical importance in packaging solutions. Despite their seemingly singular function, the variations in design, efficiency, and additional features make it imperative to choose the right one that perfectly dovetails with your specific requirements. The decision can be overwhelming, a labyrinth of technical specifications and jargon, yet, understanding what each model offers can make a considerable difference in productivity.

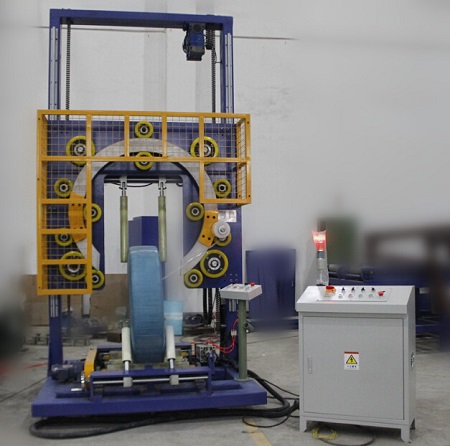

As I delved deeper into the world of steel coil wrapping machines, I realized that what seemed like a monolith of mechanical complexity was, in fact, a landscape of innovation ripe for exploration. Different models bring something unique to the table, optimizing efficiency based on specific industry needs, such as durability and speed, which are crucial determinants in this domain. This journey of understanding became a mission to find the quintessential model that strikes a perfect balance between performance and cost-effectiveness for different applications.

Which Machines are Available on the Market?

Market Overview

In the midst of my exploration, it became evident that the market offers a wide array of steel coil wrapping machines, each designed with distinctive features. From compact, semi-automated models tailored for smaller operations to highly sophisticated, fully automated machines designed for industrial giants, the marketplace caters to varied operational scales.

Model Comparison and Feature Analysis

The following data presents a snapshot of different features across top models in the market:

| Model | Automation Level | Wrapping Speed (coils/hour) |

|---|---|---|

| Model A | Fully Automated | 120 |

| Model B | Semi-Automated | 80 |

| Model C | Manual | 40 |

Feature Prioritization for Your Needs

Understanding what features are prioritized in each model is crucial. From my observations and analysis, manufacturers have prioritized versatility and ease of maintenance in more costly models, whereas budget models emphasize simplicity and cost-efficiency. Choosing between them depends largely on your operational needs and budget constraints.

Examining the Trade-offs

Delving deeper, the trade-offs between models often hinge on speed versus cost and automation versus flexibility. For instance, while Model A offers automation and high wrapping speed advantageous for large-scale operations, it is considerably expensive. Conversely, Model C emphasizes manual control, offering affordability but at the expense of speed.

Fact: Not All Machines Are Built Equally

True Fact: Fully automated machines often come with higher initial costs but drastically reduce labor costs over time.

False Fact: Semi-automated machines are slower than manual machines, offering less control to the operator.

How Does Technology Impact Efficiency?

Technological Integration

Technology has become a game-changer for steel coil wrapping machines, introducing features that streamline operations and enhance precision. I found that integrating IoT and advanced sensors with these machines has enabled predictive maintenance and reduced downtime, which is crucial for industrial efficiency.

Tech-Driven Innovations

Here’s a brief insight into technological advancements impacting these machines today:

| Technology | Impact |

|---|---|

| IoT-based Control | Reduces Maintenance Time |

| AI Integration | Enhances Precision |

In-depth Technological Evaluation

One can observe the marriage between AI and traditional mechanics in modern steel coil wrapping machines. Sophisticated motion sensors and AI algorithms predict wear and tear, allowing for timely interventions that save time and resources in the long run.

Conclusion

In wrapping up my quest to understand steel coil wrapping machines, technology clearly emerges as a pivotal element dictating efficiency and functionality. The degree to which these technological enhancements are integrated significantly impacts both the upfront and long-term cost of ownership for these machines. It's important to weigh these considerations against budget capabilities and operational demands to select the right machine.

```