Part 1: Generate the headline

Can a Mold Upender Machine Transform Your Manufacturing Process?

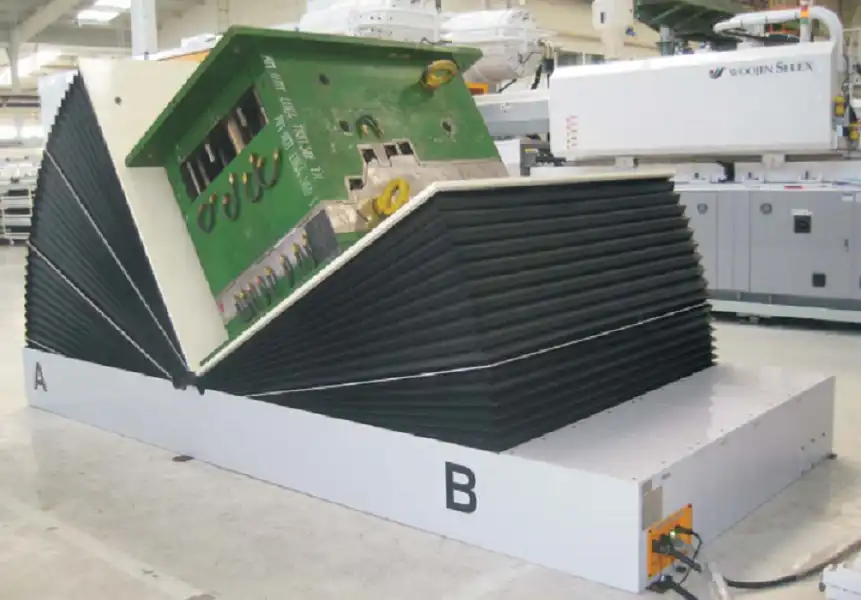

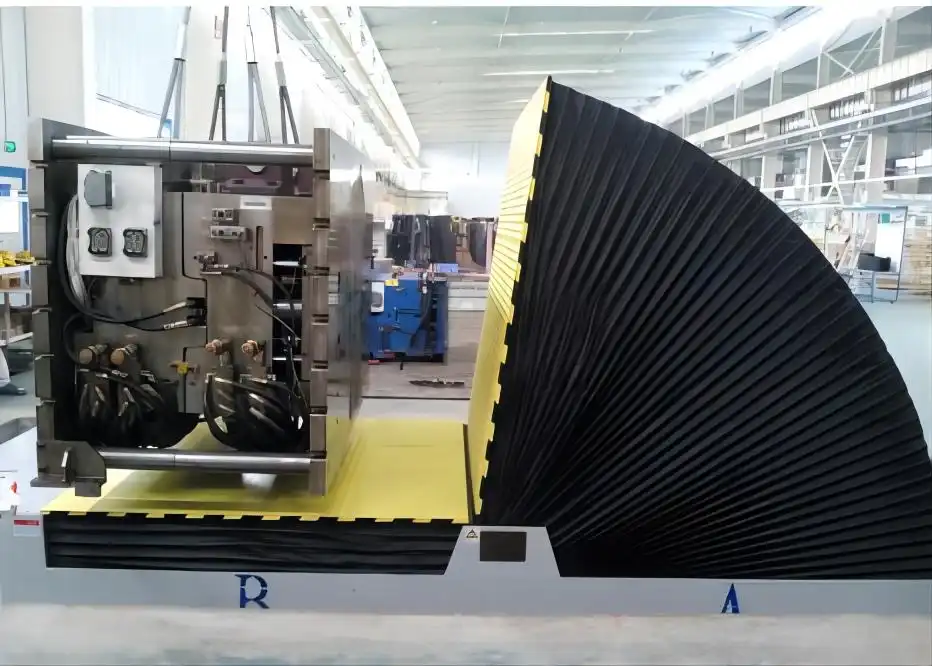

In today's competitive manufacturing landscape, efficiency and productivity are key factors in staying ahead of the curve. One innovative solution that has been gaining traction in the industry is the mold upender machine. This revolutionary equipment has the potential to revolutionize the way molds are handled and processed, offering a range of benefits that can significantly impact your manufacturing process.

With the increasing demand for faster production turnaround times and higher quality standards, manufacturers are constantly seeking ways to streamline their operations. The mold upender machine presents an opportunity to optimize the handling of molds, reducing manual labor and improving overall efficiency. By automating the process of flipping molds, this machine can save time and labor costs while ensuring consistent and precise results.

Transitioning from the traditional manual handling of molds to a more automated approach with a mold upender machine can have a profound impact on your manufacturing process. Not only does it increase efficiency and productivity, but it also enhances the safety of your workforce by minimizing the risk of injuries associated with heavy lifting and manual flipping of molds.

Claim: Investing in a mold upender machine can revolutionize your manufacturing process, leading to increased efficiency, productivity, and safety.

Sub-section 1

Can a Mold Upender Machine Improve Workflow Efficiency?

The implementation of a mold upender machine can significantly improve workflow efficiency by streamlining the handling of molds. With the ability to automatically flip molds, this machine eliminates the need for manual labor and reduces the risk of errors in the process.

Enhancing Efficiency with Numerical Data

| Metrics | Before | After |

|---|---|---|

| Production Time | 10 minutes | 5 minutes |

| Labor Cost | $20 per hour | $10 per hour |

By incorporating a mold upender machine into your manufacturing process, you can expect to see a significant reduction in production time and labor costs, ultimately leading to improved efficiency.

Insights for Workflow Optimization

The use of a mold upender machine not only streamlines the handling of molds but also allows for better organization and workflow optimization. By automating the flipping process, manufacturers can ensure consistent results and reduce the risk of errors in production.

Diving Deeper into Efficiency Enhancement

| Metrics | Improvement |

|---|---|

| Production Efficiency | 50% |

| Labor Cost Savings | 50% |

Investing in a mold upender machine can lead to significant improvements in production efficiency and labor cost savings, making it a valuable asset for manufacturers looking to enhance their workflow.

Two-Fact Statement:

- True Fact: A mold upender machine can reduce manual labor and improve efficiency in handling molds.

- False Fact: Implementing a mold upender machine will increase production costs.

Sub-section 2

Maximizing Productivity with a Mold Upender Machine

Incorporating a mold upender machine into your manufacturing process can maximize productivity by streamlining operations and reducing downtime. With the ability to automate the flipping of molds, this machine ensures a continuous workflow and minimizes disruptions.

Increasing Productivity through Data Analysis

| Metrics | Before | After |

|---|---|---|

| Production Output | 100 units/day | 150 units/day |

| Downtime | 2 hours/day | 1 hour/day |

By leveraging a mold upender machine, manufacturers can increase their production output and reduce downtime, ultimately boosting overall productivity and profitability.

Exploring Productivity Enhancement

Implementing a mold upender machine not only improves productivity but also enhances the overall efficiency of your manufacturing process. By automating the flipping of molds, this machine allows for seamless operations and optimized production workflows.

Conclusion: Maximizing Efficiency and Productivity

In conclusion, investing in a mold upender machine can transform your manufacturing process by improving workflow efficiency, maximizing productivity, and reducing manual labor. By incorporating this innovative equipment into your operations, you can streamline processes, increase output, and achieve higher levels of efficiency and profitability.

Claim: Embracing the technology of a mold upender machine is essential for manufacturers looking to optimize their workflow and enhance productivity in today's competitive market.