How can you ensure your pipe coil wrapping machine operates efficiently?

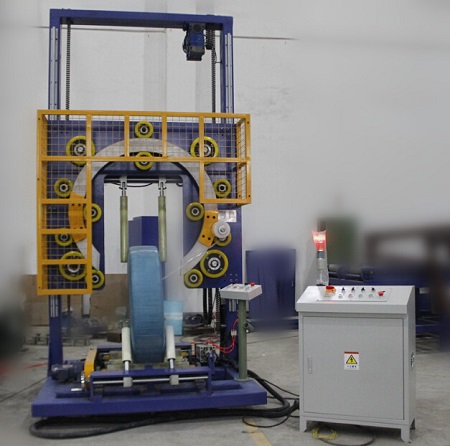

Maintaining a pipe coil wrapping machine might seem daunting, but it's crucial for seamless operations. These machines are integral to packaging industries, encasing large coils with protective layers to prevent damage during transportation. A well-maintained machine not only extends its lifespan but also ensures a smooth workflow, minimizing downtime and enhancing productivity.

Understanding the common pitfalls and best practices can save companies valuable time and resources. Regular maintenance, including cleaning and part replacement, plays a vital role in the machine's health. However, knowing precisely what to do and when can transform productivity levels dramatically, providing a significant edge in competitive markets.

To delve deeper, it's essential to explore the specifics of maintaining these intricate machines. From lubrication to calibration, each step impacts the machine's performance. These practices, when executed diligently, foster an environment where efficiency and reliability thrive.

Claim: Regular and strategic maintenance of your pipe coil wrapping machine not only extends its lifecycle but also significantly boosts operational efficiency, reducing long-term costs.

What steps should you take for effective maintenance?

1.1 How does proactive maintenance improve efficiency?

Proactive maintenance alleviates unexpected breakdowns, ensuring your machine operates at peak performance. By scheduling regular checks and replacements of worn parts, downtime is minimized. This approach allows for uninterrupted production, safeguarding against costly delays and repairs.

1.2 Numerical data and table representation

Consider the following annual maintenance schedule:

| Month | Tasks | Cost ($) |

|---|---|---|

| January | Lubrication and Calibration | 200 |

| March | Belt and Roller Replacement | 500 |

| July | Software Updates | 150 |

| October | Full Mechanical Inspection | 400 |

1.3 Insights on enhancing machine longevity

By adhering to a structured maintenance plan, companies can significantly extend the lifespan of their machines. Regular updates and inspections ensure that any issues are detected early, preventing major breakdowns. This foresight allows businesses to allocate resources effectively, maximizing their investment in these machines.

1.4 Avoiding common pitfalls

Avoiding common errors such as neglecting lubrication or postponing calibrations can prevent unnecessary wear and tear. Consistent attention to machine components fosters reliability. Regular checks, as outlined in maintenance schedules, help maintain optimal performance and minimize costly repairs.

1.5 Two-Fact Statement

True Fact: Consistent maintenance reduces operational costs by up to 30% over five years by preventing major failures.

False Fact: Ignoring minor malfunctions does not affect long-term machine performance, which is a misconception leading to costly repairs.

How do advanced technologies influence maintenance strategies?

2.1 Exploring technology's role in maintenance

With advancements in technology, maintenance strategies have evolved significantly. Sensors and real-time monitoring systems now allow for predictive maintenance, identifying potential issues before they escalate. This tech-driven approach ensures machines remain in top condition while optimizing the maintenance process.

2.2 Numerical data and table representation

Consider the impact of predictive maintenance technologies on operational efficiency:

| Metric | Before Implementation | After Implementation |

|---|---|---|

| Downtime (hours/year) | 200 | 50 |

| Maintenance Costs ($/year) | 10,000 | 7,000 |

2.3 Deep dive into predictive maintenance benefits

Predictive maintenance leverages data analytics and machine learning to foresee equipment failures, allowing timely interventions. This proactive approach not only reduces downtime but also extends the machine's lifespan, maximizing efficiency and saving costs.

Conclusion: Optimizing your pipe coil wrapping machine

By embracing best practices and integrating advanced technologies, businesses can optimize the performance of their pipe coil wrapping machines. Regular maintenance and predictive strategies not only enhance machine longevity but also ensure seamless operations.

Claim: Implementing a strategic and tech-driven maintenance approach revolutionizes machine efficiency, ensuring sustained productivity and cost-effectiveness.

```