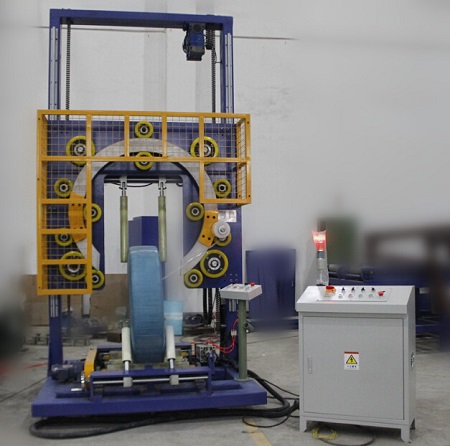

The day I first laid eyes on a steel coil wrapping machine, it was as though I’d entered a realm of endless potential for efficiency and innovation within the manufacturing industry. This mighty machine stood as a testament to how far technology had advanced, seamlessly bundling heavy steel coils with the kind of precision that would make any observer marvel at the ingenuity behind its design. Standing there, I couldn't help but wonder how these mechanical giants had transformed the handling of steel coils and pondered their key characteristics.

Having observed these magnificent machines in action, I became fascinated by the intricate dance of technology they performed. With conveyor belts smoothly transporting hefty coils and robotic arms executing their duties with split-second timing, these machines embodied the elegant synergy between man and machine. My curiosity could not be quenched; I needed to learn more about the core features that made these wrapping wonders indispensable in the steel industry.

As I delved deeper into the machinery's anatomy and function, I realized it was crucial to dissect the elements that set apart an exemplary steel coil wrapping machine from an average one. What factors, I mused, contributed to the machine’s effectiveness, and how could each component be optimized? The more I explored, the clearer the landscape of machine capabilities became.

Efficiency and Speed of Operation?

The speed at which a wrapping machine operates can significantly impact production timelines, more so in industries requiring rapid turnover. This aspect of speed is not merely about completing tasks swiftly but maintaining high-quality output while minimizing downtime. I was amazed by how manufacturers had optimized speed to achieve timely, flawless wrapping without compromising on the integrity of the packaging.

Precision and Quality Control

In our world obsessed with precision, ensuring the perfect wrap is of paramount importance. From past experiences, I know that accuracy plays a pivotal role in maintaining the condition of steel coils during transportation and storage. Machines today come equipped with advanced sensors and control systems, regularly verifying each wrap's tension and alignment. As depicted in the table below, quality assurance metrics are an ever-present consideration.

Adaptability in Handling Various Sizes

One striking feature of modern wrapping machines is their flexibility. They can accommodate a variety of coil dimensions and weights, adjusting their operations accordingly. This adaptability means that regardless of coil size, the machine ensures a snug and secure wrap each time, enhancing logistical operations. The advent of adjustable settings has proven revolutionary, allowing diversified production without the need for constant manual recalibration.

Customization Capabilities and Predictive Maintenance

Feature-rich wrapping machines offer customization options. Operators can tailor the wrapping parameters, like layer number, rotation speed, or material type, to meet specific project needs. Keeping these powerful machines in optimal condition is vital, and here, predictive maintenance becomes a valuable tool. Enhanced with IoT technologies, the machines can diagnose potential issues before they disrupt operations. See below for data overviewing predictive maintenance benefits:

| Benefit | Impact |

|---|---|

| Reduced Downtime | 30% |

| Maintenance Costs | Decrease by 25% |

True: Predictive maintenance uses real-time data from machine operations to foresee issues. False: Predictive maintenance eliminates the need for all manual checks entirely.

How Do Steel Coil Wrapping Machines Enhance Safety?

In handling heavy steel coils, safety is paramount. A well-designed wrapping machine includes numerous safety features that protect operators and bystanders. From emergency stop buttons to sensors that detect malfunctions, these machines come equipped with technology to mitigate risks associated with heavy machinery. I have come to appreciate these protective measures, knowing well how crucial they are in industrial settings.

Integration with Automated Warehouse Systems

Steel coil wrapping machines often find themselves at the heart of an automated warehouse ecosystem. They connect with other systems, like conveyors and sorting units, creating a streamlined operation from production to dispatch. The table below outlines the impact of such integration:

| Warehouse Function | Efficiency Gain |

|---|---|

| Order Fulfillment | 20% |

| Inventory Accuracy | Improves by 15% |

Innovation and the Future of Packaging Machinery

As technology advances, so does the potential for new developments in steel coil wrapping machines. Today’s focus on connectivity and artificial intelligence paves the way for even smarter machines. Soon, they may autonomously adapt to production line changes or innovations, optimizing their performance and the overall process. This horizon of endless possibilities excites me as someone vested in industrial advancements.

Conclusion

Reflecting on my journey through the fascinating mechanics and features of steel coil wrapping machines, I am filled with an appreciation for the marvels of modern engineering. As we’ve seen, these machines embody a compact symphony of precision, efficiency, and safety, continually pushing the envelope of what’s possible in manufacturing. The steel industry, and indeed many other sectors, owes a debt of gratitude to the engineers who design and perfect these ingenitive creations, setting standards ever higher. Ultimately, these machines exemplify the innovative spirit driving industry forward, harmonizing with technological advancement to deliver excellence and reliability.

```