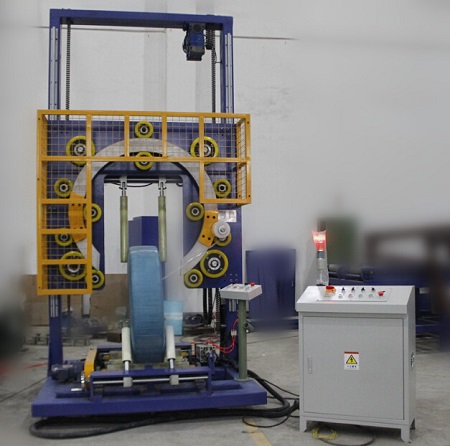

In the labyrinth of industrial innovation, one often stumbles upon the unsung heroes of machinery that silently bolster the functionality of production lines: steel coil packing machines. These machines are engineered to meticulously encase steel coils, protecting them from the merciless elements of moisture, dust, and physical damage that lurk within an industrial environment. Every day, countless tons of steel flow through the sinews of global manufacturing, each coil ensconced in its protective sleeve thanks to these machines.

Steel coil packing machines, though largely hidden from the public eye, are pivotal in ensuring the seamless transit of steel goods from mills to manufacturers. Their sophistication varies, each model tailored for different aspects of the steel packing process. From basic wrap systems to advanced wrapping lines integrated with automated features, they come with nuances that cater to a variety of industrial needs. As we delve deeper into their world, we'll unravel the intricacies bound within these mechanical protectors, answering the key question: what types of steel coil packing machines are out there?

Amidst the clang and clatter of factory floors, the transition between raw steel and finished product is a dance of precision and protection. Safety and efficiency sit at the heart of this transformation, and with steel being paramount in innumerable sectors, its safeguarding continues to be a focal point of industrial innovation. Let us explore the claim that the right machine for the right task optimally enhances this vital process.

Why Choose Automatic Steel Coil Packing Machines?

Harnessing automation in the packing process not only alleviates the need for manual labor but significantly boosts operational efficiency. Automatic steel coil packing machines often exhibit a symphony of technological advancements; they mask their intricate mechanics behind a façade of simplicity. Capable of wrapping, strapping, and even inserting protective materials within the span of minutes, these machines are a boon for large-scale manufacturers aiming to streamline production without compromising quality.

Boasting capabilities that dwarf those of their manual counterparts, automatic machines handle substantial weights and dimensions, rendering them ideal for high-output environments. While statistics demonstrate an increase in productivity by up to 40%, tables comparing cost savings versus manual labor further reinforce their expedience. They merge raw prowess with delicate precision — a commendable feat, indeed.

How Do Semi-Automatic Machines Fit In?

Semi-automatic machines bridge the dichotomy between hand-hewn craftsmanship and robotic prowess. These machines offer a modular approach, integrating manual aspects into an automated framework. By doing so, they allow flexibility in operation while still delivering a respectable output increase of roughly 25%.

| Feature | Manual Operation | Semi-Automatic Machine |

|-------------------|------------------|------------------------|

| Operator Control | High | Medium |

| Efficiency Boost | Low | Moderate |

| Cost-Effectiveness| Moderate | High |

Crafted for smaller operations where budget constrains prohibit a complete transition to automation, semi-automatic packing machines stand as a testament to ingenuity. Their structure echoes the adaptability of small industries without sacrificing the intricate touch.

Are Manual Machines Still Relevant?

Certainly, while technology races forward, manual steel coil packing machines still hold significance in niche markets. Their simplicity, affordibility and ease of maintenance render them essential, particularly in regions where small-scale production requires economical solutions. Though slower and labor-intensive, they offer meticulous care per unit packed— a quality appreciated by industries where precision trumps volume.

True or False? Automation Always Equals Better Quality

1. True: Automation generally guarantees consistency, reducing the probability of human error which plagues manual operations.

2. False: While automation enhances speed and uniformity, it doesn't always equate to superior quality, particularly in handcrafted packaging scenarios where manual expertise surpasses mechanization.

What Role Do Hybrid Machines Play in Modern Production?

In an era where efficiency is equated to innovation, hybrid machines amalgamate the advantages of both manual and automatic systems. Defined by their dual-mode operating functionality, these machines enable producers to toggle between manual and automatic operations, depending on the task complexity and volume at hand.

Feature-rich and versatile, hybrid machines cater to diverse industrial demands, accommodating variable production lines. Their dual utility enhances adaptability within unpredictable production environments.

| Feature | Manual Mode | Automatic Mode |

|-------------------|-----------------|------------------------|

| Task Complexity | High | Low |

| Customization | Broad | Narrow |

| Adaptability | Excellent | Good |

Diving deeper into such machines reveals that their real power lies in their flexibility, particularly beneficial for operations where sudden shifts in production requirements are frequent. Data illustrates that implementing hybrid systems results in a 30% overall efficiency improvement.

Concluding Thoughts on the Evolution of Steel Coil Packing Machines

As we conclude this exploration, a claim emerges clear: steel coil packing machines, in their myriad forms, are indispensable within industrial ecosystems. From automatic wonders of efficiency, through semi-automatic versatility, up to the familiar and comforting hands-on manual methods, the spectrum of machines available caters to every conceivable need and scale. The intertwined paths of tradition and innovation continue to merge, producing ever more refined solutions for steel packing, illuminating the promise of further advancements on the industrial horizon.

Ensuring steel coils are enshrouded within layers of robust protection is not just a necessity — it's a testament to the unyielding pursuit of perfection endemic to modern industry.

```