As I stood in the bustling factory, the relentless clanging and rhythmic thumping of machinery filled the air. My gaze was drawn to the operations on the factory floor, where the latest steel coil packing machine was in full swing, its synchronized movements a testament to technological innovation. The machine functioned like clockwork, an intricate dance of cogs, belts, and rollers that encapsulated steel coils with precision.

The world of manufacturing is ever-evolving, driven by the need for efficiency and precision. In the steel industry, the demand for high-quality packing solutions has led to the development of advanced machines that can handle complex tasks with ease. Among them, the steel coil packing machine stands out, offering a blend of sophistication and functionality. But what makes these machines so vital, and what features should one consider when selecting the best option for their needs?

Standing at the nexus of technology and industrial need, I decided to delve deeper and explore the core features of steel coil packing machines. The information I found unveiled a tapestry of functionalities that ensured the productivity and safety of steel coil packing - a surprisingly complex process that impacts everything from logistics to final product quality.

##1. How Does a Steel Coil Packing Machine Work?

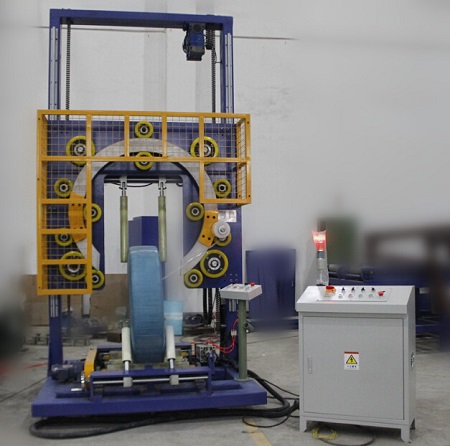

The initial fascination draws from the simple allure of what these colossal machines achieve daily. A steel coil packing machine operates as the linchpin in ensuring coils are protected during transit and storage. It’s not just a machine; it’s a robust system tailored to streamline packaging operations effectively.

My exploration revealed that the process begins with a mechanism that deftly handles the placement of the coil onto a conveyor. The machine then meticulously wraps the coil, generally employing stretch film or other protective materials to ensure it remains intact during movement. Watching this harmonious sequence, I was struck by the seamless integration of each stage of operation.

The specifications of these machines are as varied as their applications. For instance, many models incorporate user-friendly digital interfaces that allow custom settings tailored to different coil sizes. Others come equipped with adjustable tension controls, ensuring the wrap remains snug yet without damaging the steel surface.

| Feature | Description |

|--------------------|--------------------------------|

| User Interface | Digital, customizable settings |

| Tension Controls | Adjustable for different loads |

These key attributes not only facilitate efficiency but also enhance the versatility of the machinery, allowing it to adapt to various industrial requirements.

The steel coil packing machines often complement this functionality with high-speed operational capacity, ensuring that even under demanding conditions, the workflow remains seamless and uninterrupted. Understanding these mechanisms gives one a clearer insight into how they contribute to a more efficient supply chain.

A steel coil packing machine might boast the ability to wrap up to several hundred coils per hour, depending on its design and operational parameters. However, what stands unparalleled is the machine's ability to conform precisely to predefined specifications, guaranteeing that each coil exits the packaging bay in its optimal condition for transport.

| Parameter | Capability |

|----------------|-----------------|

| Wrapping Speed | Up to 300 coils/hour |

One might assume that such machines operate without fault, but the truth holds a nuanced story. While they are designed for high efficiency, human oversight remains an essential component, allowing operators to adjust operations based on real-time conditions, thereby maintaining continuous workflow.

True: Steel coil packing machines enhance logistics by safely securing coils for transport.

False: These machines fundamentally replace all human oversight in manufacturing processes.

##2. Why Are Key Features Important in Steel Coil Packing Machines?

While observing the packing machine amidst the factory's bustle, I realized choosing the right features is vital for achieving specific operational goals. Each feature carries weight beyond its apparent function — they shape productivity, quality, and overall output.

One major aspect to consider is automation. Advanced machines leverage automation to reduce manual intervention, thereby increasing output while minimizing error margins. In fact, advanced models include sensors and auto-correct functionalities, which play critical roles in monitoring processes, ensuring that every coil is wrapped with precision.

| Feature | Importance |

|-------------------|----------------------------|

| Automation | Increased productivity |

| Error Monitoring | Enhanced output quality |

The sophistication of these machines is a reflection of the evolving demands in industries reliant on steel coils, where packing efficiency translates directly to cost savings and improved product quality. Such innovations not only alleviate production pressures but also forge a path toward more sustainable industrial practices.

The dedication to precision is what solidifies a steel coil packing machine’s role in the manufacturing ecosystem. Yet, the pursuit of quality isn’t achieved solely through automation; it demands a thoughtful integration of design and performance, revealing a complex dance between machine and material.

Thus, understanding the nuanced complexity woven into each feature of a steel coil packing machine is crucial. It reinforces the machine's indispensable role and highlights its potential to revolutionize packaging operations beyond traditional methodologies.

In conclusion, my journey through the realms of steel coil packaging has granted me a newfound respect for these intricate machines. Each feature, whether it pertains to automation, error monitoring, or adaptability, collectively drives the machine's efficiency and elevates operational standards within the steel industry.