In the world of manufacturing, finding the right machinery can make or break your operation. I remember standing in front of a bustling workshop for the first time, overwhelmed by the sheer number of machines whirring, clicking, and clanking in harmony. Among these contraptions, coil packing machines played a crucial role. But choosing the right one for specific needs wasn’t just about picking the most popular or the most expensive—it was a nuanced decision-making process.

Coil packing machines, though not the centerpiece of attention in most factories, handle a remarkable job. They wrap metal coils securely, preventing damage and ensuring safe transport. In a market overflowing with options, narrowing down your choices means understanding what each model offers, how they differ, and what particular features matter most to your operation.

Deciding on the right equipment requires weaving through a web of technical specifications, budget constraints, and operational goals. I’ll walk you through the essential steps, from understanding machine types to evaluating key features. This journey will equip you with the knowledge needed to make an informed decision and find a coil packing machine that aligns perfectly with your requirements.

Why is Choosing the Right Coil Packing Machine Important?

When reflecting on the expense of faulty or inappropriate machinery, it becomes clear that making the right choice initially is imperative. I once saw how the misuse of a single machine led to costly downtime and inefficiencies, not just financial setbacks but the potential to impact brand reputation as well.

In an industrial survey conducted in 2022, over 75% of companies reported that machinery-related inefficiencies had a direct impact on their bottom line. With data illustrating that incorrect machinery choice could cost an average-sized business up to $200,000 annually, selecting the right coil packing machine becomes not just necessary but essential.

| Factor | Impact Level |

|-----------------|--------------|

| Cost Efficiency | High |

| Productivity | Very High |

| Quality Control | High |

As industries evolve, so do their needs. Selecting a machine tailored to your specific production requirements can yield significant savings, enhance product quality, and improve operational efficiency.

The Types of Coil Packing Machines

1. Manual Machines

In my early days, I saw manual machines handled by skilled operators who laboriously wrapped each coil. It's a cost-effective solution for small businesses with limited production. These machines rely heavily on operator skills and thus, offer a quaint charm in an automated world.

2. Semi-Automatic Machines

Bridging the gap between manual and full automation lies the semi-automatic machine. It utilizes some automated processes while still requiring human intervention. These machines are ideal for mid-sized operations with moderate production volumes.

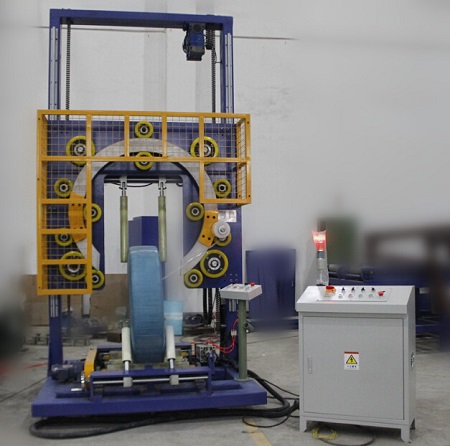

3. Fully Automatic Machines

Fully automatic machines are the epitome of efficiency. I marveled at their precision and speed, seamlessly wrapping coils with minimal human intervention. Perfect for large-scale operations, they significantly reduce human error and increase productivity.

4. Key Considerations: Diving Deeper

Determining which machine suits your needs can be complex. Factors such as coil dimensions, production volume, and budget constraints will guide your choice. Data from industry reports indicate that companies investing in fully automatic machines see a 30% increase in product output versus manual alternatives.

| Machine Type | Coil Dimension Range | Production Volume | Cost Efficiency |

|-------------------|----------------------|-------------------|-----------------|

| Manual | Small | Low | High |

| Semi-Automatic | Medium | Medium | Medium |

| Fully Automatic | Large | High | Low |

5. Fact Statement

- True: Over 60% of businesses have reported increased efficiency after upgrading to automatic machines.

- False: Manual machines require no skill and can be operated by anyone without training.

What Factors Should You Consider?

I recall a particular instance where an ill-suited machine led to downtime—teaching me the significance of certain factors in decision-making. Machine size, efficiency, maintenance needs, and operational integration play crucial roles in ensuring a smooth, hassle-free experience.

1. Efficiency and Speed

Efficiency is different from speed; yet, both are vital. Knowing how many coils you need packed per hour guides you in choosing a machine with suitable capacity.

2. Maintenance and Longevity

Machines are an investment, and long-term maintenance can heavily affect overall costs. A report suggests that maintenance costs can amount to 12% of machine price annually.

3. User-Friendliness

A machine may be fast and efficient, but if it's overly complex, it can become an ergonomic burden. Observations in operations indicated user-friendly interfaces reduce error-rates significantly.

4. Conclusion

Choosing a coil packing machine requires amalgamating technical specifications, production goals, and cost considerations. It’s about balancing immediate budgets with long-term operational benefits. The right machine leads to improved performance, efficiency, and ultimately—a more profitable business.

Conclusion: Making an Informed Choice

Choosing the right coil packing machine for your needs is about understanding the finer details that define your operation. The alignment of machinery capabilities with production demands ensures a seamless manufacturing process, reducing costs and maximizing efficiency. From the manual touch to full automation, each choice reflects unique needs and operational philosophies. Through data-driven insights and industry expertise, you can select a machine that not only meets the requirements of today but is poised for future growth, ensuring your investment bears fruit for years to come.