In the ever-evolving landscape of industrial packaging, finding the right equipment to protect and secure coils during transportation and storage is crucial. As a manufacturing professional, I have witnessed firsthand the critical role that coil packing machines play in enhancing productivity and ensuring the safety of various products. Coil packing machines are versatile, and their diversity offers solutions tailored to specific needs. This article delves into the types of coil packing machines that dominate the market and the unique attributes that each brings to the table.

Understanding the sprawling variety of coil packing machines can be overwhelming. From vertically oriented machines to horizontal options, manufacturers must navigate this landscape to choose the best fit for their operations. Selecting the appropriate machine not only improves efficiency but also boosts the integrity and quality of the packed coils. The decision-making process involves weighing factors like budget, the nature of the product, and the desired speed of operations.

Transitioning from traditional packing methods to automated coil packing solutions has been pivotal in many industries. Automation minimizes human error, enhances consistency, and significantly speeds up the packing process. Machines are now equipped with advanced sensors and software that ensure precision, reducing the chances of product damage during shipping. Manufacturers need to consider both present and future packing demands to make an informed investment in coil packing solutions.

[claim] The importance of choosing the right coil packing machine cannot be overstated—the impact is felt throughout the supply chain, from production lines to the end customer.

What Are the Key Categories of Coil Packing Machines?

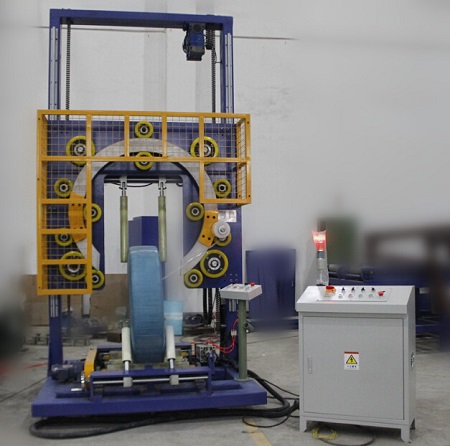

Horizontal coil packing machines have gained popularity for their ease of use and versatility. These machines are designed to wrap coils horizontally, making them ideal for products that require more stable handling during the packing process. They are particularly efficient when dealing with larger coil sizes and provide a seamless packing method that protects against environmental factors.

When examining the types of coil packing machines, it's essential to delve into the specific features and specifications that differentiate them. One key category is the vertical coil packing machine, often regarded for its compact footprint even while handling heavy-duty operations. Here's a simple overview of their value proposition:

| Machine Type | Operation Type | Ideal For |

|---|---|---|

| Horizontal Coil Packing | Automated wrapping | Large coils |

| Vertical Coil Packing | Compact production lines | Space-saving solutions |

Horizontal coil packing machines typically feature image-based monitors that streamline operation, ensuring that even minimal supervision yields high-quality outputs.

In recent years, the advent of automated systems has drastically improved the speed and accuracy of coil packing machines. Automated machines are now equipped with intelligent programming that allows for seamless transition between different coil sizes without manual adjustments. This capacity to adapt on-the-fly saves considerable time and effort for manufacturers aiming to maintain varied product lines without downtime.

True or False: Automated coil packing machines can only handle products of a predetermined size. The reality is that modern advancements have enabled these machines to adjust to different dimensions, offering incredible flexibility. True. However, early models of coil packing machines indeed lacked this adaptability, often requiring lengthy downtime for adjustments. False.

How Does One Optimize the Use of Coil Packing Machines?

The integration of coil packing machines into an existing production line can significantly change operational dynamics. Introducing these machines ensures more efficient resource utilization and consistency across packed units. Businesses have reported improved throughput rates and reduced material wastage, translating into direct cost savings.

Knowing the exact dimensions and weight of the coils you intend to pack is the starting point to optimizing machine usage. Further, it's crucial to choose coil packing machines that allow for easy recalibration and maintenance. Here's a detailed breakdown of efficiency enhancements through strategic machine selection:

| Efficiency Attribute | Description | Impact |

|---|---|---|

| Automation | Reduces operator error | 10-20% increase in packing speed |

| Adjustability | Handles different coil sizes | Reduced downtime |

Advancements in software have revolutionized how coil packing machines function. Sensor technologies and IoT (Internet of Things) capabilities have dramatically increased the machine's precision and functionality, allowing manufacturers to transition from batch-processing to just-in-time packing strategies.

Conclusion

As industries evolve, coil packing machines have become a linchpin in facilitating seamless logistics. The right choice of a coil packing machine not only improves operational efficiency but also ensures the end product reaches consumers without degradation. As I have highlighted, understanding the various types of available coil packing machines and integrating them smartly into manufacturing processes enhances not just the present output but positions companies strategically for future demands.

[claim] Investing in the right coil packing machine is a strategic move that promises robust returns by enhancing the entire packaging lifecycle.